Among the many packaging materials, paper is light and soft, with a wide range of raw materials, low cost, diverse varieties, extremely convenient processing, economic and practical, and suitable for mechanized large-scale production. According to the function, it can be divided into ordinary packaging paper, special packaging paper, food packaging paper, commodity printing packaging paper, etc.

Paper commonly used for packaging boxes: kraft paper, corrugated paper, white cardboard, gray cardboard, box cardboard, special paper, candy paper, etc.

(1) Kraft paper:

It is a tough and water-resistant packaging paper with high tear strength. It is usually yellowish brown and brownish yellow, and has a wide range of uses. It can be divided into packaging kraft paper, waterproof kraft paper, moisture-proof kraft paper, rust proof kraft paper, typesetting kraft paper, process kraft paper, insulating kraft paperboard, kraft paper, etc. It is often used to make paper boxes, paper bags, envelopes, record cases, files, etc. Tenacity and water resistance are important characteristics of kraft paper. Most kraft paper is produced in the United States, Canada and Scandinavia. Semi bleached or fully bleached kraft pulp is light brown, cream or white. The original kraft paper can be bleached into different gray or even white, which is suitable for making large packaging paper bags for large transportation. Kraft paper usually has two to seven layers. In special cases, plastic and metal foils can be processed into their bags due to the need of moisture resistance. The large packaging bags with this composite structure are particularly strong and are often used to load construction cement, chemical products, grain and feed. Refined kraft paper is an improved product of ordinary kraft paper. It has light and bright color, clean appearance, high smoothness, good strength and good printing effect. Now better envelopes and information bags are made of kraft paper.

(2) Corrugated paper:

As early as more than 130 years ago, the brothers Edward Healy and Edward Allen, British people, invented the method of pressing corrugated paper as the lining of hats to absorb juice. In 1858, Britain had the first patent for manufacturing corrugated paper. In 1871, American Albert Jones used single-sided corrugated paper to package glass bottles and obtained a patent. At that time, single-sided corrugated paper was used. It was not until the end of the 19th century that the United States began to study the use of corrugated paper to make packaging and transportation boxes. In 1914, Japan began to produce cartons, and in 1920, double corrugated cardboard came out, and its use was rapidly expanded. During the first World War, wooden boxes accounted for 80% of transport packaging, while cartons accounted for only 20%. stay

During the Second World War, cartons accounted for 80% of the transportation packages. Corrugated boxes in China started relatively late and were only popularized in 1954. As a transport package, corrugated box has the characteristics of low cost, light weight, easy processing, high strength and easy recycling. Corrugated paper is a plate-like material made of hanging paper and corrugated paper formed by processing with corrugated sticks. It is generally divided into single corrugated board and double corrugated board. Corrugated board is made of surface paper, inner paper, paper core and corrugated paper processed into corrugated waves by bonding.

According to the size of the corrugated, it can be divided into five types: A, B (transport outer packing box), C (beer box), e (single packing box) and f (micro corrugated).

Because the packaging container made of corrugated cardboard has its unique performance and advantages in beautifying and protecting the inner goods, it has a great advantage in the competition with a variety of packaging materials and is one of the most important packaging materials used by countries in the world today. This is a package with very little ink. The whole package is folded from a piece of cut corrugated paper, which does not need to be pasted, greatly reducing the cost of manual production. The selection of environmentally friendly, light and loose materials improves the lightness and compression resistance of the product package, and facilitates the transportation of the product.

(3) White cardboard:

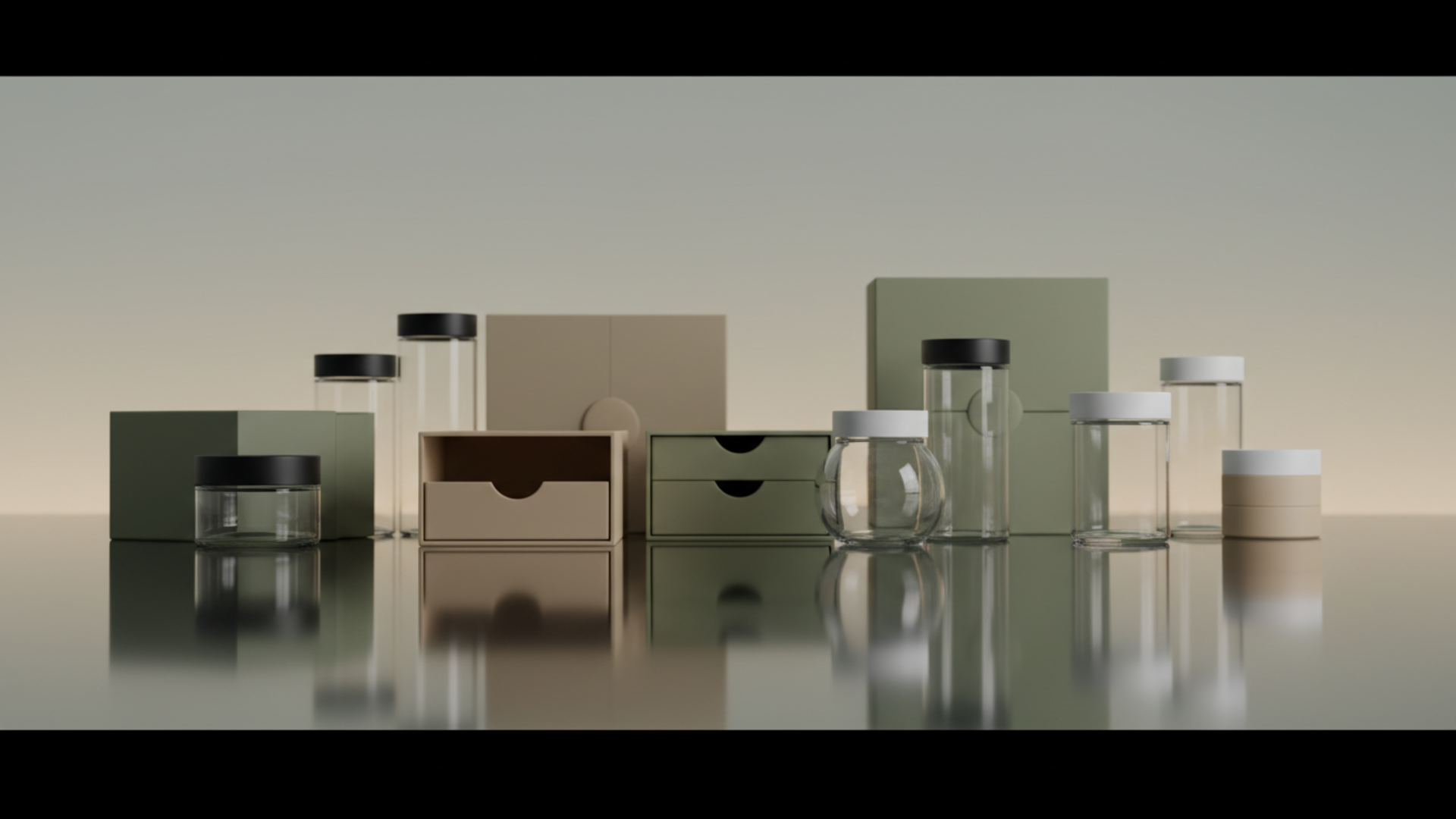

White paperboard is a kind of thick and strong white paperboard made of pure high-quality wood pulp. It is a single-layer or multi-layer combined paper made entirely of bleached chemical pulp and fully sized. It is generally divided into blue and white single and double-sided coated paperboard, white coated paperboard and gray coated paperboard. White card paper is hard, thin and crisp, with high color purity, more uniform ink absorption, better folding resistance, and wide uses, such as making various high-grade packaging boxes,

This kind of paperboard is characterized by high smoothness, good stiffness, neat appearance and good uniformity, which is suitable for printing and product packaging.

It is divided into three levels: A, B and C. generally, there are 200g, 250g, 280g, 300g, 350g and 400g white cardboard. The functions of different grams of white cardboard are also different.

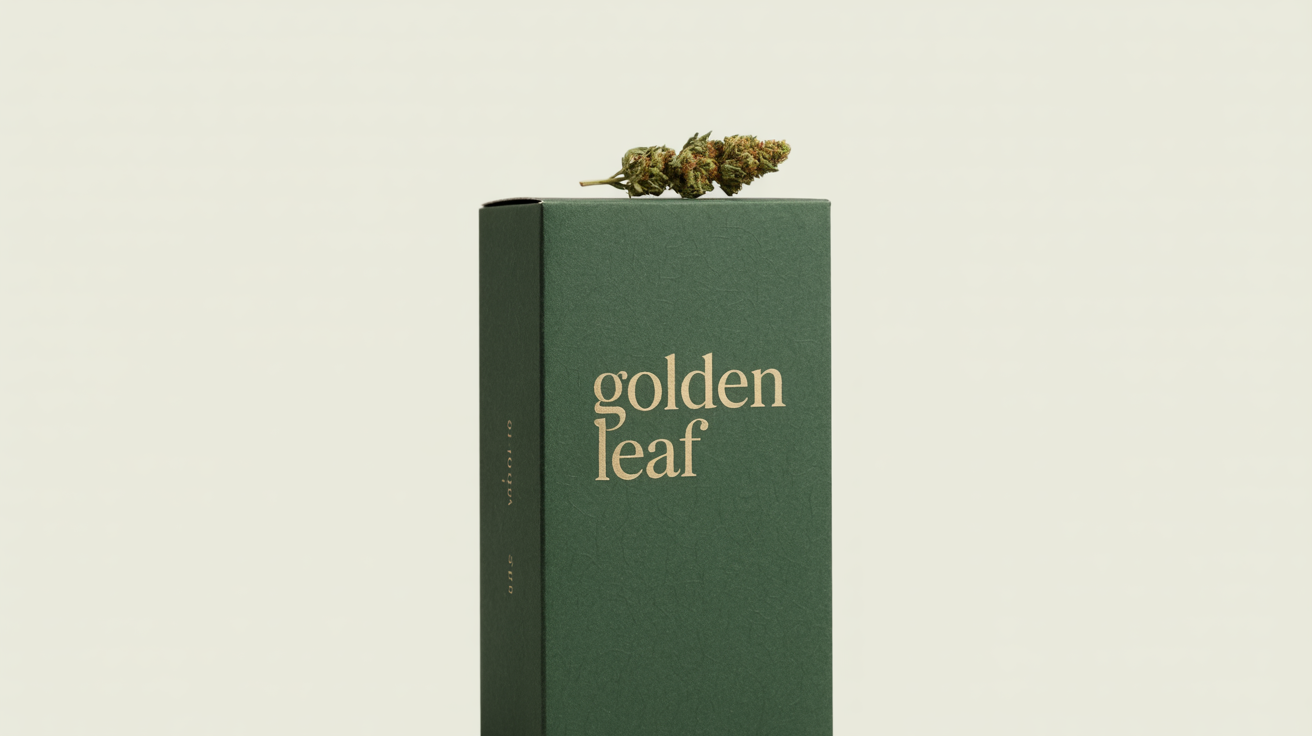

SAS cube is a brand-new aircraft meal concept of SAS Nordic airlines. This unique cube design will bring a simple and high-quality pure Nordic dining experience. The design is inspired by the natural scenery and culture of Scandinavia. The exterior uses soothing white and is painted with quiet and elegant patterns of Norwegian mountains, Danish coast and Swedish forest nature. Opening this cube shaped lunch box is like unpacking a brand-new mobile phone package or a box of high-grade chocolates. The design is very delicate, and its design that meets the needs of passengers makes the use process more convenient. Considering the space limitation during flight, a spare space is reserved for passengers to continue working, reading or watching movies. Every detail shows the designer's appropriate care.

(4) Grey cardboard:

Commonly used in packaging boxes, it is commonly known as gray cardboard because its back is gray. This kind of cardboard is suitable for single-sided printing cartons, whose density is far lower than that of white cardboard. It is also often used for mounting pit paper, which is commonly known as cardboard. The packaging boxes made in this way are more protective for products.

(5) Carton board:

Also known as hemp board, it is a relatively strong board specially used for making outer packing cartons. The surface is smooth, the color is light yellow or light brown, and it has high mechanical strength, folding resistance and burst resistance. It can be divided into ordinary and advanced. Ordinary ones use chemical unbleached straw pulp as raw material, while advanced ones use brown ground wood pulp, kraft wood pulp, cotton pulp or hemp pulp. Cardboard is widely used.

(6) Special paper:

It generally refers to the paper with good paper quality, high price, special purpose and small output. There are many kinds of special paper, which is the general name of all kinds of special purpose paper or art paper. Now, art paper such as embossed paper is collectively called special paper. Special paper has a wide range of applications, high performance and added value, but its domestic production rate is low.

(7) Candy paper

It is a kind of paper material that is widely used for packaging. After printing packaging patterns and waxing, it is used for packaging candies. It has good water resistance and air impermeability. Besides being used for candy packaging, it is also used for moisture-proof packaging of bread and other foods.

Paper packaging materials are non-toxic, tasteless, pollution-free, safe and hygienic. After strict process and technical conditions control, various kinds of paper packaging materials can meet the packaging needs of different commodities and will not pollute the packaging contents.

Therefore, paper is the most used in food packaging, accounting for about 70% of the whole packaging industry. Since most of the food packaging paper is directly imported food, which is in direct contact with food, the materials selected for food packaging must meet the requirements of non-toxic, oil resistant, waterproof, moisture-proof and sealing.

Among all kinds of food packaging materials, plastic has the characteristics of portability, cheapness and good barrier property, and has always occupied a large share in the food packaging market. However, due to the harmfulness of plastics to human health and its extremely difficult natural degradation, it has caused serious environmental pollution and restricted its further development in the field of food packaging.