With the continuous improvement of paper packaging technology, a large number of CBD carton packaging with novel structure and beautiful decoration continue to emerge, which is deeply welcomed by consumers; But at the same time, it also puts forward a series of new topics for packaging manufacturers. For example, some carton designs are difficult to achieve packaging automation, and occupy too much storage space, resulting in an increase in packaging and transportation costs. In addition, with the improvement of people's living standards, higher requirements are also put forward for the comfort and convenience of daily necessities packaging. Therefore, packaging manufacturers should fully consider ergonomics when designing and manufacturing folding cartons.

For a long time, 420 Packaging has been engaged in the research and teaching of packaging structure. In teaching and daily life, we constantly observe and study, and summarize the following elements that should be considered in the structural design of CBD carton packaging.

1. Usage of CBD Packaging Materials

At present, the economy is developing rapidly, but the ensuing environmental problems are also worrying. According to relevant information, the annual economic losses caused by environmental problems have exceeded 100 billion US dollars, of which packaging waste is increasing at a rate of 10% every year, of which urban garbage accounts for 25%. This has aroused great attention. More and more people are aware of the importance of natural resources. The call for green packaging for goods is rising day by day. This requires packaging workers to find ways to save packaging materials in the process of structural design, on the one hand, to save money and energy; On the other hand, reduce waste.

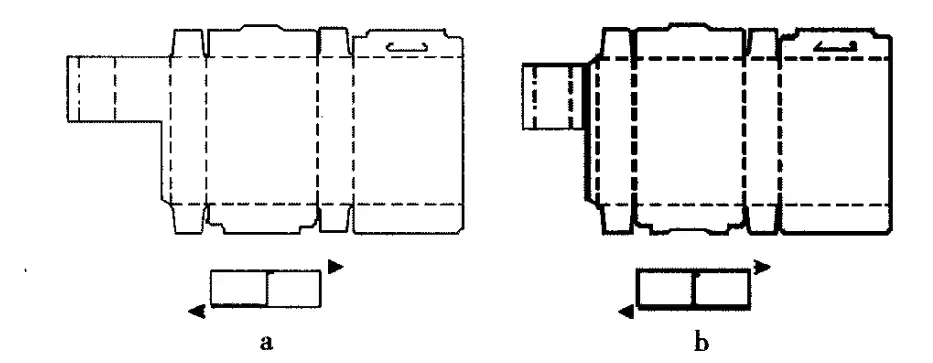

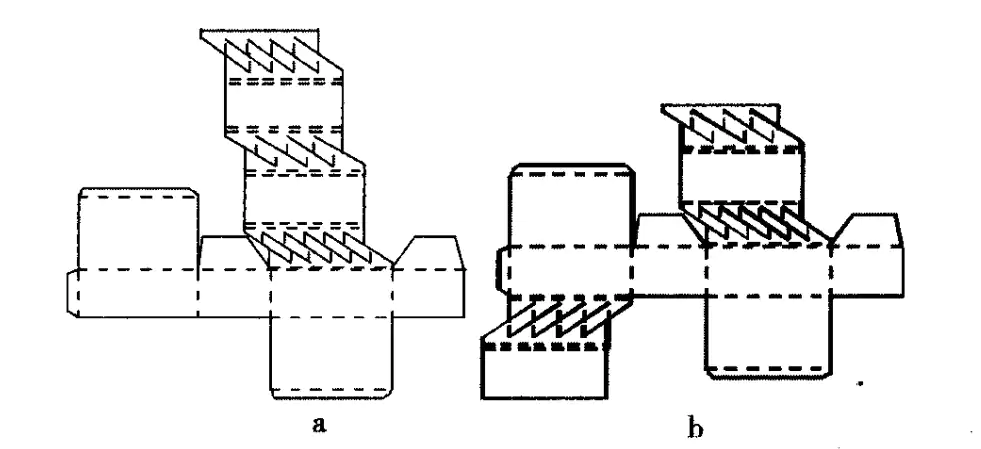

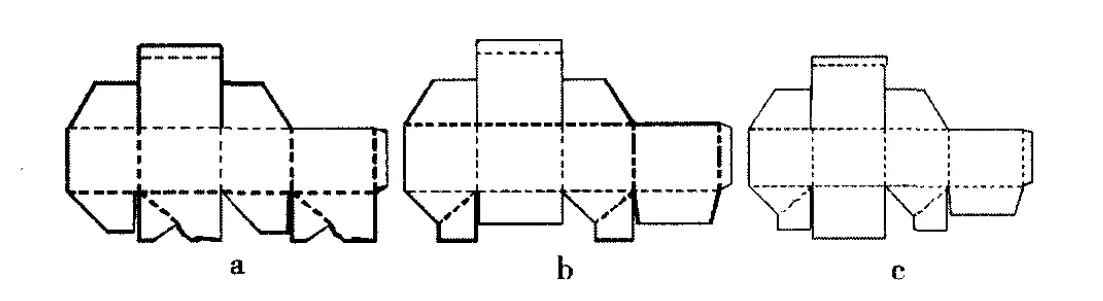

Fig.1 SEAL END carton

Fig. 1 a shows the paperboard required for the structure diagram of the normal design, and Fig. 1b shows the use of the carton paperboard after the improved design. In the transverse direction, figure 1 b saves the overlapping part of the spacer plate and the body plate and draws it separately, leaving only the adhesive part; In the longitudinal direction, figure 1 b digs out a notch in the bottom plate with the same shape as the protruding part of the cover plate, which is conducive to making large plates and saving paper materials. Of course, the amount of cardboard saved by a carton is very limited, but a small amount adds up to a large amount. For a large number of cartons with an annual output of one million or even ten million, the savings can not be underestimated. If we pay attention to this problem, we will not only reduce the production cost for manufacturers, but also make great contributions to green environmental protection.

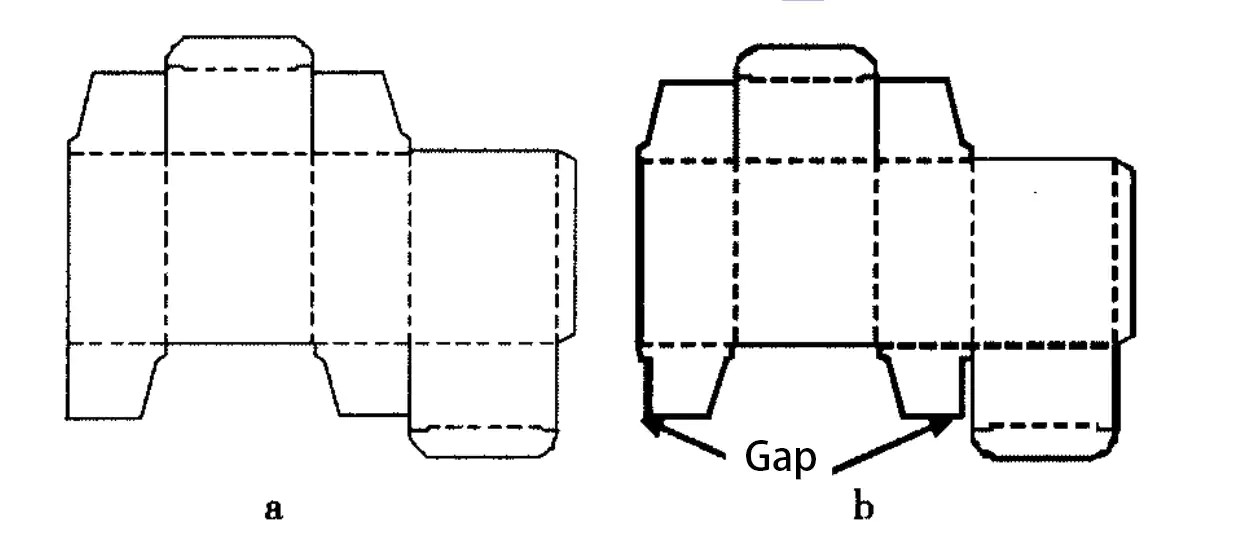

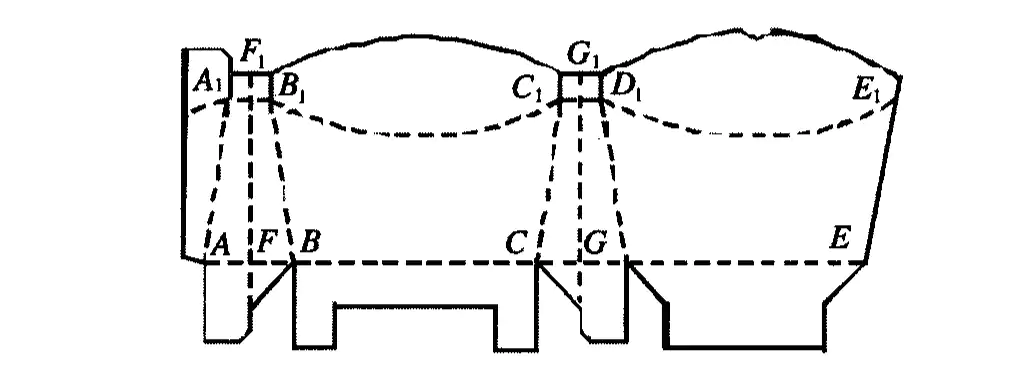

Fig.2 Multi-spacing linercarton

Fig. 2 is another typical example of saving packaging materials. In order to achieve multiple partitions, an extension plate must be added to the body plate to facilitate the design of the partition lining format. Fig. 2a is the original structural design, and the partition structure can be fully realized. However, FIG. 2B shares the extension plate on two body plates, which saves at least one carton height in the longitudinal direction, and ensures the molding of one sheet of cardboard.

2. Convenience of Mechanical Operation

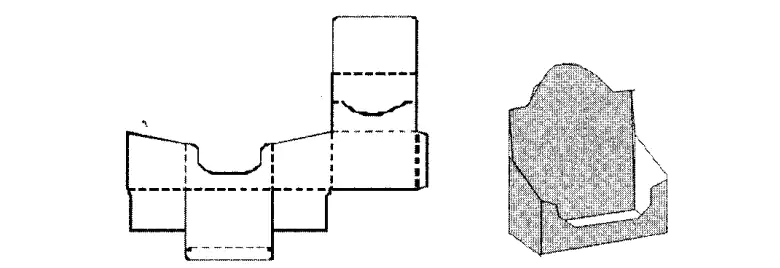

Fig.3 French-Reverse-Tuck-End carton

When the carton is hand proofed, it is completely free of problems to draw, die-cut, and then fold it manually. However, in the fully automatic production line, there will be a situation that the mechanical grippers have no way to start. Therefore, a gap must be opened next to the dust flap, as shown in Fig. 3, so as to facilitate the mechanical device to control the box blank of the carton and facilitate the complete automatic production of packaging.

Fig.4 Display carton

In the design of cartons produced on the packaging linkage machine production line, the printing surface must also be considered. The display box shown in Fig. 4 can be printed on one side on the cover plate, and the decoration performance of the carton can be guaranteed.

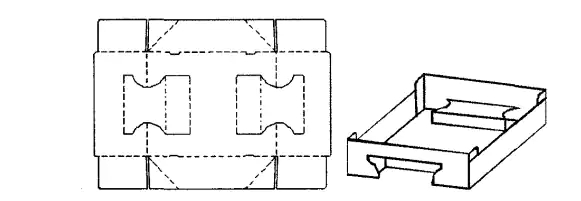

3. Convenience of Stacking and Transportation

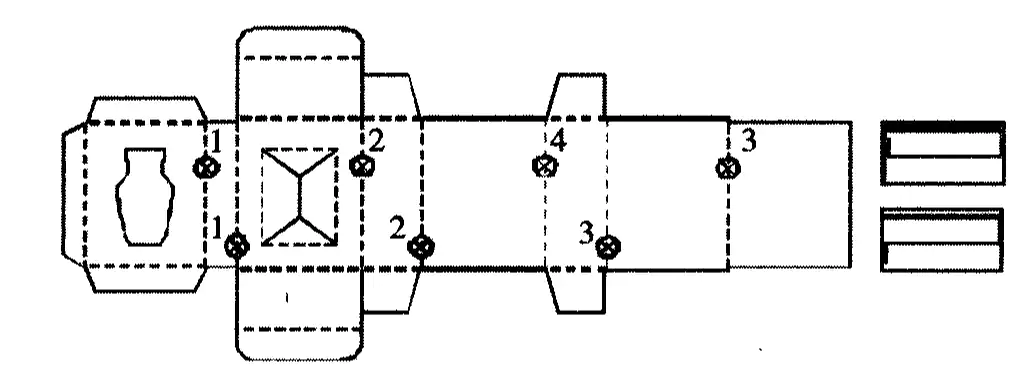

Most of the time, what consumers see are CBD packaging cartons after three-dimensional molding. In fact, except for a few special-shaped cartons or cartons that can not be produced automatically, most of the carton body joints are bonded in the flat state, and this flat state goes through counting, stacking, packing, storage, transportation and other links until the box body is stretched before packaging the contents on the automatic packaging line. To realize the flat state of the carton, we must find a way to design the operation line of the carton. The operation line needs to be folded 180 degrees during the automatic bonding process of folding cartons. The design principle of the operation line is that the forming process of cartons on the automatic gluing machine is the simplest (the number of flat folding is the least) and it is convenient for the automatic operation of the gluing machine. Using the operation line to design the structure of cartons will greatly reduce the cost of packaging cartons or cartons during transportation and storage. Generally, cartons can use the forming line of cartons as the operation line. In Fig. 5, there are two kinds of operation line designs, all of which are designed using molding lines.

Fig.5 Designofoperating lineforbook-likecarton

For some special-shaped folding cartons, the forming folding line cannot make the two ends of the box blank align and overlap after being folded flat. At this time, two vertical operation lines must be redesigned, and the operation line should be extended to pass through the cover plate (flap) or the bottom plate (flap) as appropriate. Lines FF and GG in Fig. 6 are redesigned operation lines, not molding lines.

Fig.6 Abnorm alcarton

4 Ergonomics

Ergonomics is the study of various factors such as anatomy, physiology and psychology in a certain working environment; Study the interaction between human and machine and environment; Research on how to consider work efficiency, human health Safety, comfort and other issues [. According to the research of ergonomics, there needs to be a certain balance and coordination between the human body and the object, that is, the product must adapt to the needs of human anatomy and physiology. For packaging, on the premise of meeting the basic performance, it should be as light and labor-saving as possible, easy to open, comfortable and safe to use.

Fig.7 Carton for CBD Edible Packaging

As shown in Fig. 7, it basically belongs to the four point glued box type. It is two protruding parts supported from the bottom of the box and the box body. This design can kill two birds with one stone, not only forming a handle, but also a fixed place for four drinks. The size of the handle part shall meet the requirements of ergonomics and highlight the humanization characteristics.

5. Strength of Packaged CBD Products

Fig.8 Carton with self-lock bottom

Strength is the essential factor of packaging. If the strength fails to meet the requirements, the protection of packaging will not be reflected. The self-locking bottom shown in Fig. 8a and 8b has a defect, that is, the bottom is not closed. If the contents are irregular or have sharp corners, it is easy to puncture the bottom of the box; If it is designed in a box shape as shown in Fig. 8C, the purpose of increasing strength can be achieved by replacing only one half bottom plate with a full bottom plate. In the actual design, we will find that the above elements are mutually permeable. The improved design in Fig. 2 not only saves materials but also facilitates mechanical operation. But sometimes they are contradictory. As shown in Fig. 1, although materials are saved, the procedure will be complicated for mechanical gluing, because the spacing part is separated from other parts, which will virtually increase the workload of mechanical operation; In Fig. 8c, although the strength is increased, the amount of paperboard is also increased. These elements run through the whole packaging process, from material selection, structural design, packaging production, transportation and even sales. In addition to the above factors, carton design should also consider the nature of the packaged product itself, the recycling of cartons, etc.]. The nature of the product itself, such as form, purpose, mode of transportation, mode of sales, etc., should be analyzed specific to the specific product。 In short, when designing the carton structure, we should follow the scientific concept of development, make appropriate choices according to the specific situation of the design, and achieve the lowest cost and the best benefit.