Whether you’re launching gummies, chocolates, baked goods, or beverages, the right cannabis edible packaging must do three things at once: meet regulations, protect product quality, and build trust with consumers. This guide covers the essentials—from child-resistant formats and labeling to barrier materials, sustainability, and operations—so you can move from prototype to shelf with confidence.

What Counts as “Edible Packaging”?

“Marijuana edible packaging” includes any primary or secondary pack that directly holds or ships infused foods and beverages—think gummy pouches, chocolate flow-wraps, child-resistant tins, rigid cartons, and multi-serve beverage carriers. The package’s job is to:

Protect

-

Maintain potency and flavor by limiting oxygen, light, and moisture.

-

Prevent breakage, melting, or odor leaks.

Comply

-

Meet child-resistance, warning, and labeling rules where sold.

-

Follow dosage and universal symbol requirements where applicable.

Communicate

-

Clearly state THC per serving/pack, ingredients, allergens.

-

Convey brand quality, safety, and responsible use.

Important: Cannabis regulations are state-specific and change often. Always verify rules for the state(s) where your products will be sold and have legal counsel review final labels before print.

Compliance & Labeling Essentials

While details vary by jurisdiction, most states require some version of the following:

-

Product identity (e.g., “Infused Gummies”).

-

Net quantity (weight/volume, servings per package).

-

THC/CBD content per serving and per package (e.g., 10 mg/serving, 100 mg/package).

-

Ingredients in descending order; allergens (e.g., milk, soy, nuts).

-

Nutrition facts (often required for food products).

-

Batch/lot ID, manufacture date, best-by or use-by.

-

Warning statements (state-specific), including age restrictions and impairment warnings.

-

Universal cannabis symbol and “Keep out of reach of children” language.

-

Origin & license info: manufacturer/distributor name, license # (as required).

-

QR code linking to COA, batch testing results, and product education.

Best Practice: Maintain a living “labeling matrix” spreadsheet that maps each target state to its exact warnings, font rules, min icon sizes, and placement restrictions. Update it whenever regulations change.

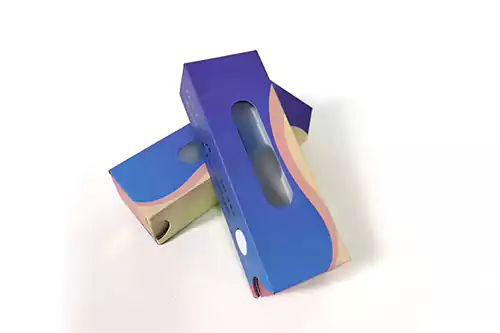

Child-Resistant (CR) Formats & Testing

Most states mandate child-resistant packaging for edibles. Common options:

-

CR pouches (sliders, press-to-close + secondary CR feature)

-

CR tins (push-and-turn or tool-assisted lids)

-

CR cartons (folding cartons with locking mechanisms)

-

CR bottles/jars (CRC closures with tear bands or tabs)

CR performance is generally validated through protocols modeled on Poison Prevention standards (e.g., child panel testing and senior-friendly access). Request test reports from suppliers and ensure the exact size/closure you buy is covered by the certificate.

Tip: CR isn’t just about the closure—film thickness, zipper spec, and heat-seal parameters also affect child resistance.

Shelf Life: Barrier Materials & Freshness

Edibles degrade with oxygen, moisture, light, and heat. Choose structures based on your product’s sensitivity:

| Material / Structure | Strengths | Trade-Offs | Common Uses |

|---|---|---|---|

| Metallized PET / PE (mOPET/PE) | Good oxygen & light barrier; cost-effective | Not transparent; recyclability varies | Gummy or chocolate pouches |

| Aluminum foil laminations | Excellent O₂/H₂O barrier; odor control | Stiffer; potential “crinkle”; higher cost | High-potency chocolates; strong odor items |

| Nylon coextrusions | Puncture resistance; form-fill-seal friendly | Moderate barrier; needs sealing dial-in | Bars, baked goods |

| Glass or PET jars with CRC lids | Premium feel; display; recloseable | Heavier; freight cost; light ingress | Gummies, mints (add desiccant, O₂ scavenger) |

Freshness toolkit: desiccants for moisture-sensitive SKUs, oxygen absorbers for oxidation control, low-permeation films, and cold-chain for heat-sensitive chocolates.

Sustainability Without Sacrificing Safety

Consumers value low-impact packaging, but cannabis rules and CR needs limit options. Practical pathways:

-

Right-sizing: avoid oversized cartons and excessive void fill.

-

Mono-materials where possible (e.g., PE/PE) to improve sortability.

-

Post-consumer recycled (PCR) content in films or rigid containers.

-

Refill + reuse programs (state rules allowing).

-

Transparent claims: avoid vague “eco-friendly” language; specify % PCR, certifications, or recycling streams.

Branding, Design Files & Print Methods

Regulatory clarity and brand storytelling can coexist. Consider:

-

Hierarchy: dosage & warnings must be instantly legible; flavor and brand cues come next.

-

Imagery rules: many states restrict cartoons/youth-appealing visuals; verify before design.

-

Print methods:

-

Digital print for low MOQs, fast turns, seasonal SKUs.

-

Flexo/gravure for high volumes and precise color control.

-

Cold/foil, spot UV, soft-touch for premium lines (check scuff resistance).

-

Data-ready labels: reserve space for batch stickers, variable data, or date/lot stamps.

Design handoff checklist (packaging dieline): AI/PDF dieline, bleed/safe areas, color profile (CMYK + Pantone if needed), linked fonts (or outlines), image res ≥300 dpi, regulatory layers on top, variable-data zone marked.

Operations: MOQ, Lead Times & QC

Typical MOQs

-

Digital pouches/labels: ~500–2,000 units

-

Custom films (flexo/gravure): 5,000–25,000+

-

Rigid jars/tins (decorated): 1,000–10,000+

Lead Times

-

Stock + label: 1–2 weeks after art

-

Custom pouches: 3–6 weeks after proof

-

Custom rigid: 6–10+ weeks (tooling may add time)

Quality Controls

-

Incoming QA: film gauge, zipper spec, CR lot certs

-

On-line: seal integrity, print registration, barcode scan

-

Finished goods: aging tests, odor transfer, drop tests

Work with co-packers familiar with edibles: they’ll dial in sealing temperatures, dwell time, and fillers to avoid bloom, stickiness, or smearing.

Step-by-Step Packaging Workflow

-

Regulatory scoping: confirm target states, dosage rules, symbols, CR obligations.

-

Product stability study: heat/light/humidity exposure; define barrier targets.

-

Structure selection: choose CR format and film/rigid structure meeting barrier goals.

-

Dieline + creative: place warnings, nutrition, dosage, and QR/COA space.

-

Supplier vetting: request CR test reports, food-contact declarations, and samples.

-

Pilot run: seal tests, drop tests, accelerated aging; validate label fit.

-

Compliance review: legal sign-off; archive master artwork and proofs.

-

Production: pre-press proof approval; in-line QC; retain samples.

-

Post-launch monitoring: retailer feedback, consumer complaints, CAPA loop.

Top Mistakes to Avoid

-

Non-matching CR certs: buying a “similar” pouch size not covered by the supplier’s test report.

-

Missing variable-data space: no room for batch sticker or date/lot stamp.

-

Under-spec’d barrier: gummies turning sticky or stale due to poor MVTR/O₂ specs.

-

Youth-appealing design: cartoonish graphics that trigger regulatory rejections.

-

Ignoring freight & storage: heat-sensitive chocolate in non-insulated shipping.

FAQ

Do all marijuana edibles require child-resistant packaging?

Most states require CR for edibles, either as primary or in combination with a CR exit bag. Always check your target market’s current rule set and keep vendor CR certificates on file.

What should be on the label for infused gummies?

Product identity, net quantity, THC per serving/package, ingredient list, allergens, nutrition facts (if required), warnings, universal symbol, batch/lot, dates, license info as required, and a QR code linking to COA/testing.

Which pouch film is best for odor control?

Foil-based or high-barrier metallized laminations typically outperform clear films. Add proper seals and consider odor-absorbing liners for strong-aroma SKUs.

How do I balance sustainability with compliance?

Start with right-sizing and mono-materials where possible. Use PCR content and be precise in claims. Ensure the format still meets CR and barrier requirements.

What MOQs should a startup expect?

Digital print keeps MOQs low (hundreds to a few thousand). Fully custom films and decorated rigids often start in the thousands to tens of thousands.

Can I use the same package in multiple states?

Often yes, with modular labels: keep a base compliant design and apply state-specific stickers (warnings, symbols) to reduce SKU complexity.

Do I need nutrition facts for edibles?

Frequently required for food products. Work with a nutrition lab or software validated for your formulations; verify local rules before printing.

How do I verify child-resistance?

Request third-party CR test reports from the exact supplier and for the exact size/closure. Keep certificates and lot records in your quality file.

What causes gummies to sweat or clump?

Excess moisture, poor MVTR barrier, high storage humidity, or insufficient coating. Use desiccants, improve film barrier, and control warehouse climate.

Any tips for small batch limited editions?

Use stock CR pouches or jars with high-quality digital labels; leave space for variable data. This keeps cost and timelines manageable.

Compliance Reminder

Disclaimer: This guide is for educational purposes and does not constitute legal advice. Cannabis regulations differ by state and change frequently. Consult qualified counsel to review your packaging and labels before production.