What Is Pre-roll Packaging? (Complete, Practical Guide)

Pre-roll packaging is the set of containers and boxes designed to hold and sell pre-rolled cannabis joints (cones). It covers both primary packaging (directly touching the pre-roll—like tubes, tins, or paper cartons) and secondary packaging (outer sleeves, multipacks, or display units). Good pre-roll packaging balances compliance (CR/TE), product protection (freshness, odor control), brand presentation, and sustainability.

1) Core Goals of Pre-roll Packaging

- Compliance: Child-resistant (CR) and tamper-evident (TE) where required; correct warning symbols and labels.

- Protection: Preserve moisture and terpenes, control odor, and prevent mechanical damage.

- Branding: Print area for logos, finishes, and storytelling; shelf-ready presence.

- Sustainability: Recyclable materials, mono-material choices, minimal plastic, or plastic-free options.

2) Common Packaging Types

Single Pre-roll Tubes

- Materials: Glass (premium/inert), PET or PP plastic (lightweight/cost-effective), aluminum tubes (opaque/protective).

- Openings: Push-and-turn caps or squeeze-top tubes (often CR-rated).

- TE Options: Shrink bands, tear tapes, security seals.

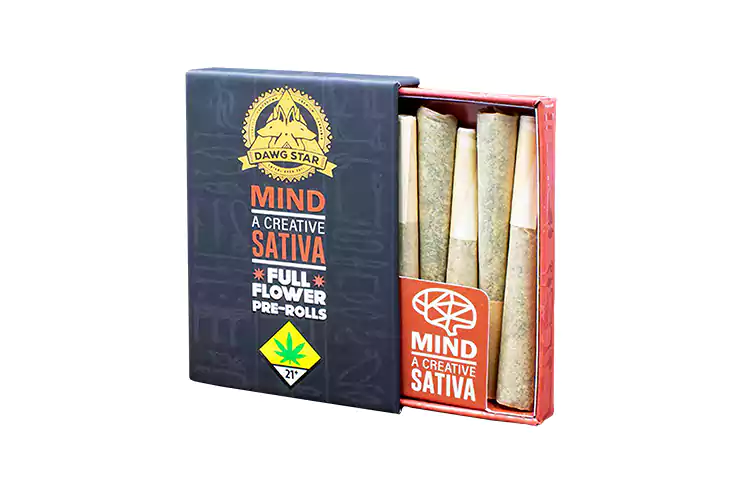

Multipack Boxes & Tins

- 2/3/5/7/10-count formats; paperboard sleeves with CR sliding drawers or metal tins with CR sliders.

- Inserts (cardboard or molded pulp) keep cones secure and reduce breakage.

- Room for humidity packs in premium SKUs.

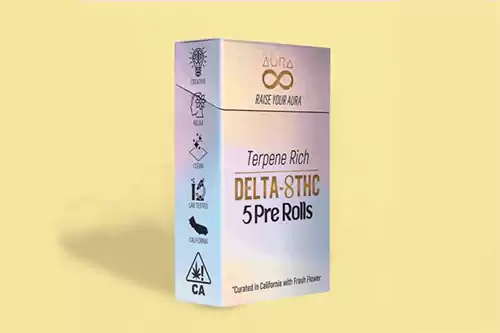

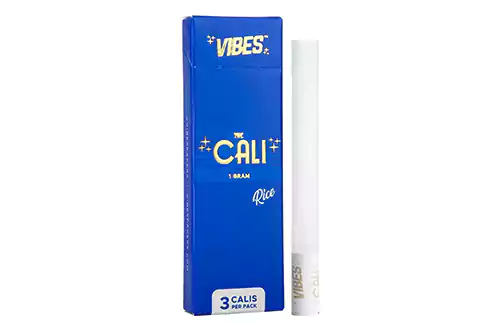

Paper Cartons / Slim Packs

- Lightweight, high printability, easy to recycle; CR achieved via sleeves/locking tabs.

- Great for brand-forward minimal plastic programs.

Display-Ready Boxes (PDQ)

- Outer cases that convert to counter displays—inner primary packaging still carries CR/TE burden.

3) Standard Pre-roll Sizes (Reference)

| Common Cone Length | Approx. Imperial | Typical Fill | Packaging Fit Notes |

|---|---|---|---|

| 84 mm | ≈ 3.31″ | ~0.5 g (mini/short) | Provide 3–5 mm headspace; internal diameter clearance ~1–2 mm at the widest point. |

| 98 mm (Slim / “98 Special”) | ≈ 3.86″ | ~0.5–0.75 g | Match insert cavities to tip width; avoid rattling to prevent paper edge wear. |

| 109 mm (King) | ≈ 4.29″ | ~1.0 g | Use thicker-wall tubes/tins or snug trays; check fit with filters/tips used. |

Tip: Different cone brands have different shoulder/tip diameters—always prototype with your actual cones and grinding density.

4) Materials & Finishes

| Material | Pros | Cons | Common Finishes | Sustainability Notes |

|---|---|---|---|---|

| Paperboard (cartons) | Recyclable, great print area, lightweight, low cost | Lower moisture/odor barrier unless lined | Matte/Gloss coating, soft-touch, foil stamp, emboss/deboss, spot UV | Prefer FSC stock; water-based coatings; mono-material (no plastic windows) for easier recycling |

| Glass (tubes/jars) | Inert, excellent barrier, premium look | Heavier, breakable, higher shipping cost | Amber/opaque, frosted, lined caps/gaskets | Widely recyclable; pair with paper labels |

| Plastic (PP/PET) | Durable, lightweight, CR features available | Perceived as less eco-friendly; odor control varies | Squeeze-top, push-and-turn caps, liners | Use single resin where possible; post-consumer recycled (PCR) options |

| Metal (tins/tubes) | Opaque, robust, reusable; good light barrier | Higher unit cost; dent risk if thin | CR sliders, custom emboss, internal trays | Metal is highly recyclable; avoid mixed liners |

5) Compliance: CR, TE & Labeling (Overview)

- Child-Resistant (CR): In many markets, cannabis packages must pass standardized CR testing (e.g., criteria derived from 16 CFR 1700.20)—children should not be able to open; adults (including seniors) should.

- Tamper-Evident (TE): Clear visual evidence if opened (e.g., shrink bands, breakable seals, tear strips). Some jurisdictions require both CR and TE at the point of sale.

- Labeling: Typically includes a universal cannabis symbol (where applicable), net contents, licensee info, batch/lot, warnings, and sometimes cannabinoid content and a UID/QR for tracking.

Important: Regulations vary by state/province/country and change frequently. Always confirm current rules with the local regulator’s website or legal counsel. This guide is informational, not legal advice.

6) Design for Freshness, Odor & Fit

- Moisture/Terpene Retention: Choose barrier materials, lined caps, and consider humidity control packs (often 58% or 62%) in multipacks.

- Odor Control: Use tight seals, gaskets/O-rings, and thicker walls if needed; verify by practical sniff tests and accelerated aging.

- Light Protection: Amber/opaque substrates or interior metallized liners to reduce oxidation.

- Fit & Protection: Inserts/trays cradle each cone; maintain minimal play to avoid crumpling or tearing at the tip.

7) Typical CR Mechanisms

- Push-and-Turn (press cap down, then twist)

- Pinch-and-Slide (squeeze latch while sliding a drawer)

- Squeeze-Top Tube (apply pressure at marked points)

Request third-party CR test reports from suppliers and validate with production samples.

8) Manufacturing & Cost Notes

- MOQs & Lead Times: Paperboard often has lower tooling cost (dies) and moderate MOQs; plastics/metals may require molds and higher MOQs.

- Print & Finishes: Reserve effects (foil/emboss/soft-touch) for key SKUs to control cost; verify scuff and rub resistance.

- Kitting: Decide if humidity packs, inserts, and seals are applied at converter, co-packer, or in-house.

- Tolerance Stack-ups: Confirm dimensions with your actual cones, filters, and grind—fit issues usually come from diameter variance.

9) Quality Assurance Checklist

- Compliance Docs: CR test report (where required), TE verification, material/ink/adhesive compliance statements.

- Fit Tests: Length headspace 3–5 mm; diameter clearance 1–2 mm; no rattling or tip abrasion.

- Seal Integrity: Air-tightness/odor tests (practical and accelerated aging).

- Humidity Control: With/without humidity pack comparison over time.

- Label Review: Symbols, warnings, net contents, batch/UID, license info placed on correct panels.

- Drop/Transit: Carton and tube/tin survive normal parcel handling without crush or pop-open.

10) Sustainability Options

- Use FSC-certified paper, water-based coatings, and avoid plastic windows.

- Prefer mono-material designs (easier recycling) and label adhesives that release.

- Consider PCR plastics or reusable tins for premium lines.

- Right-size packaging to reduce freight emissions and shelf waste.

11) Buyer’s Worksheet (Decide Faster)

- Market & Rules: Which jurisdiction? CR? TE? Symbols? Font sizes?

- Format: Single tube or 2/3/5/7/10-pack? Paper, plastic, glass, or metal?

- Cone Spec: 84/98/109 mm; target fill (0.5/0.75/1.0 g); filter length/diameter.

- Freshness: Humidity pack needed? How many days on shelf?

- Branding: Which finishes matter most? (foil, emboss, soft-touch, spot UV)

- Operations: Where are TE bands applied? Who inserts humidity packs and trays?

- Budget/Lead Time: MOQ, tooling, unit target, and launch date.

12) FAQs

Do pre-roll packages have to be child-resistant?

In many regions, yes. Cannabis regulations often require CR packages (and TE) at retail. Check your local regulator’s latest guidance.

What is tamper-evident packaging for pre-rolls?

Any feature that clearly shows if a package was opened—e.g., shrink bands, breakable seals, or tear strips.

Which size should I choose—84, 98, or 109 mm?

Match length to your target fill and consumer preference: ~0.5 g (84 mm), ~0.5–0.75 g (98 mm), ~1.0 g (109 mm). Always prototype with your own cones.

How do I keep pre-rolls fresh?

Use adequate barrier materials, lined caps/gaskets, and consider humidity packs (commonly 58% or 62%) in multipacks.

Glass vs plastic vs metal—what’s best?

Glass offers premium barrier and feel; plastic is light and cost-effective with CR options; metal is durable and reusable. Choose based on brand positioning, regulations, and sustainability goals.

What should my labels include?

Typically: cannabis symbol (if required), product name, net contents, licensee info, batch/lot, warnings, and any jurisdiction-specific items (e.g., UID/QR, cannabinoid data). Confirm locally.

13) Glossary

- CR (Child-Resistant): Packaging that children cannot open easily but adults can.

- TE (Tamper-Evident): A visible indicator shows if the package was opened.

- PPPA / 16 CFR 1700.20: U.S. framework and test procedures for CR packaging.

- PDP (Principal Display Panel): The main brand/consumer-facing label panel.

- UID: Unique identifier used for batch/traceability in regulated markets.

Need help turning this into a spec sheet or RFQ package (with dielines, fits, and label panel templates)? Share your market, cone size, and target pack count, and you’ll get a ready-to-send brief.