At-a-glance

Fit rule: internal compartment length ≈ cone length + 4–8 mm clearance

Divider inserts: prevent rattling, but can pinch cones if too tight

Paperboard reality: sturdy protection, usually not airtight on its own

CR basics: “child-resistant” has a legal definition and a test method

Example context: some blank paperboard 5-pack boxes are described as rigid paperboard with optional drawer/magnetic/button-lock closures and optional divider inserts—see a representative spec page here.

Real-life meaning

“Blank pre-roll box” usually means the outer box has no pre-printed branding or warnings yet—so it’s ready for your label. That blank space is helpful, but it also means you must confirm you have enough room for whatever warnings or identifiers your area requires.

The most common disappointment isn’t the outside size—it’s the inside size. A box can look roomy, but the internal compartments (especially with a divider insert) can be tight enough to crush cones or crease papers.

One more reality check: paperboard protects against bending and scuffs. It does not automatically mean “odor-tight” or “humidity-controlled.” If freshness or odor control matters, focus on the inner protection method (liner, inner sleeve, tube, humidity control) rather than assuming the outer box does it.

Data tables: common sizes & fit planning

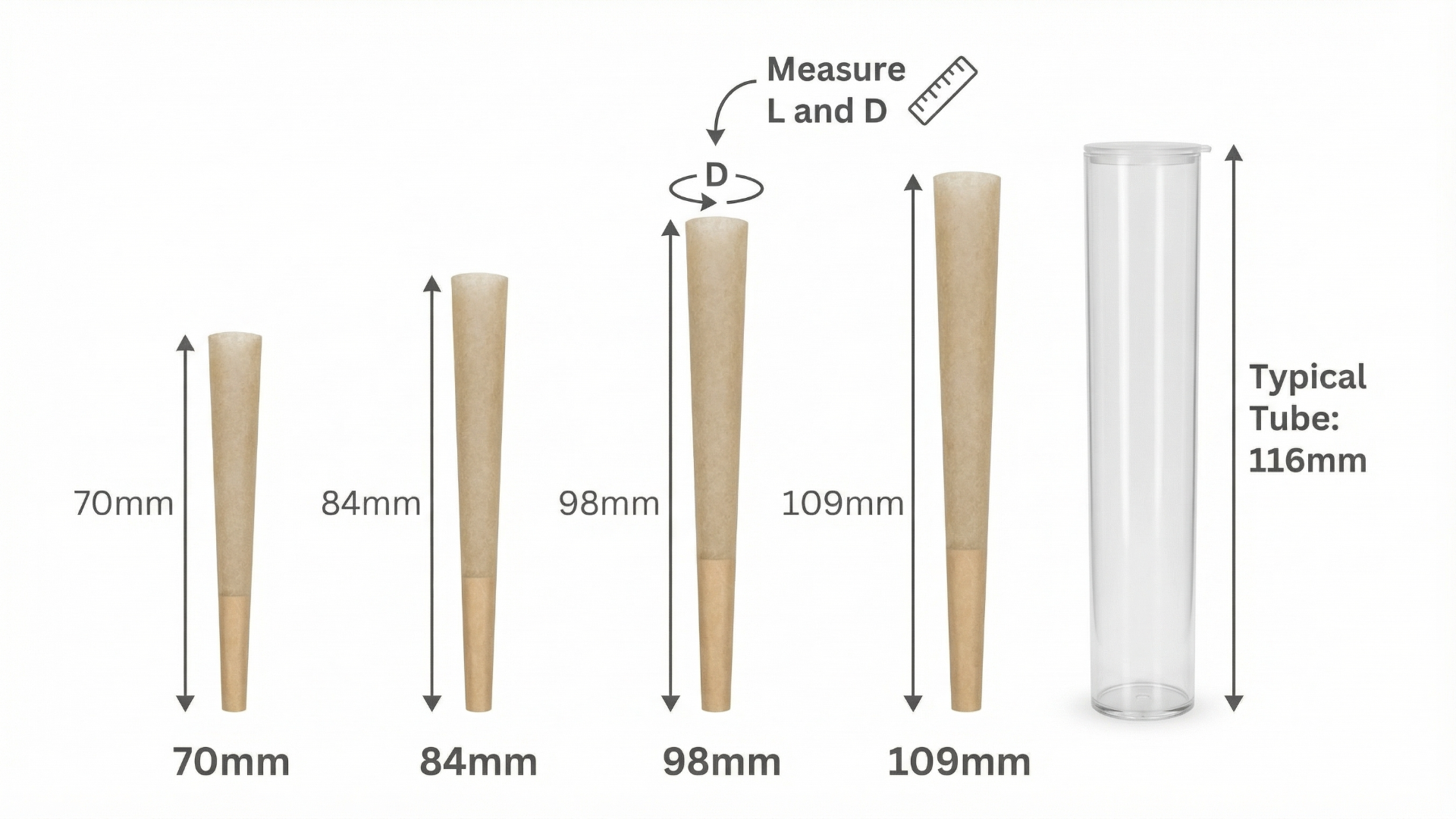

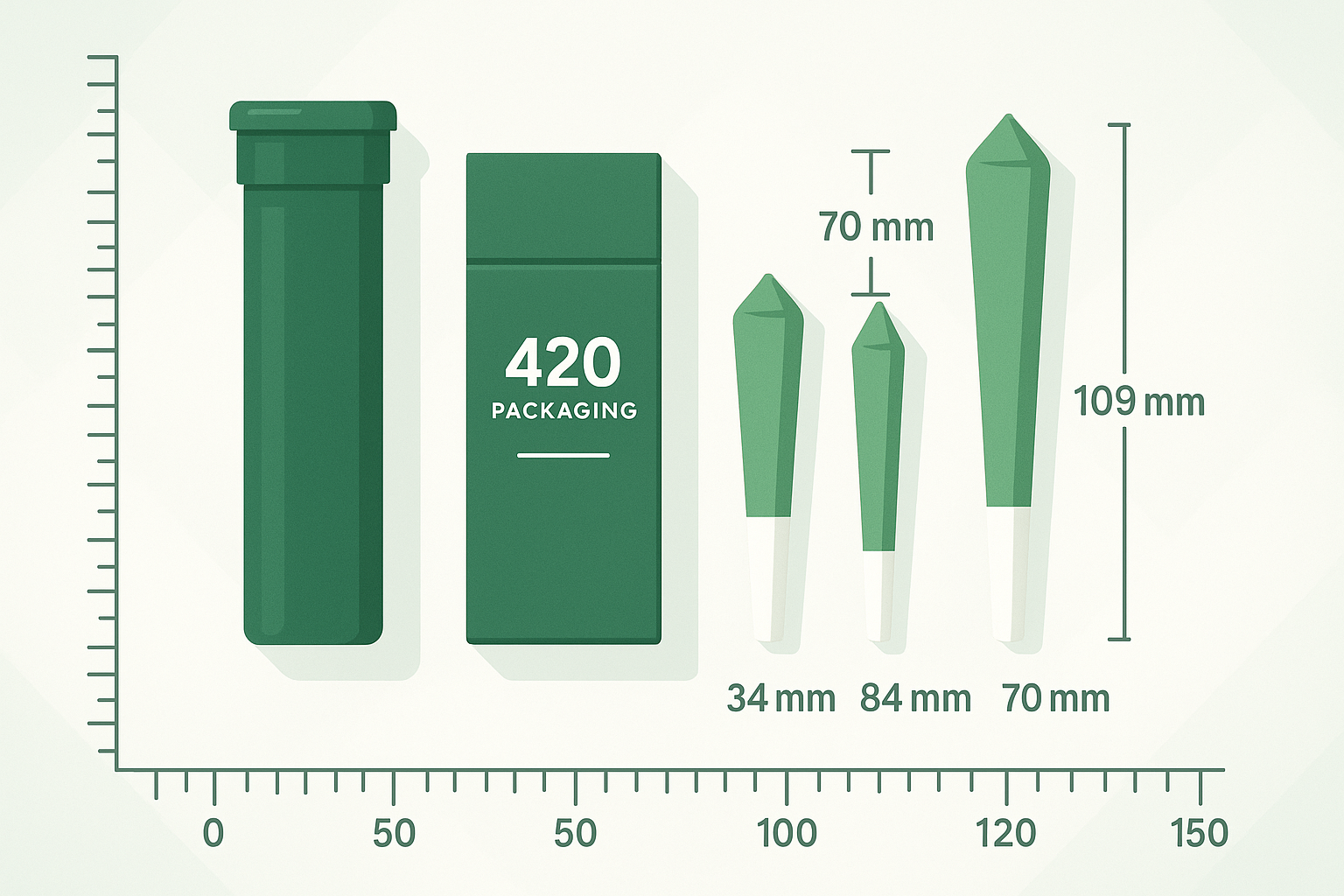

The chart below uses widely referenced cone lengths (70 mm, 84 mm, 98 mm, ~110 mm) as a starting point. For example, RAW lists 84 mm (1¼) and ~110 mm (king size) cone options, plus a 98 mm “in-between” size on its product pages (84 mm & 110 mm reference, 98 mm reference). Diameters vary by cone style; Custom Cones USA publishes example diameter measurements for common cone sizes (diameter examples).

| Common cone length | Length in inches | Suggested internal compartment length (adds 4–8 mm clearance) | Why the clearance matters |

|---|---|---|---|

| 70 mm | 2.76 in | 74–78 mm (2.91–3.07 in) | Prevents tip crumpling when the lid closes; leaves room for minor variability. |

| 84 mm | 3.31 in | 88–92 mm (3.46–3.62 in) | Helps avoid paper creasing if the divider is snug or the box flexes in a pocket/bag. |

| 98 mm | 3.86 in | 102–106 mm (4.02–4.17 in) | Reduces “end pressure” that can loosen the twist or dent the filter end. |

| 110 mm | 4.33 in | 114–118 mm (4.49–4.65 in) | King-size cones often fail in “almost long enough” boxes—small shortfalls show up fast. |

Tip: If you’re using a divider insert, treat each divider channel as the “compartment” you’re sizing—some inserts taper or pinch near the ends.

What features change the fit (and what they really do)

| Feature | Plain-English meaning | Fit impact | When you should care |

|---|---|---|---|

| Rigid paperboard | Thicker board that resists bending | Protects against crushing from outside pressure | Pockets, backpacks, shipping, or stacked storage |

| Drawer-style closure | Inner tray slides out | Great for divider channels; can add friction at the ends | If tips crumple during sliding, you need more length clearance |

| Magnetic closure | Flap closes with embedded magnets | Less pinch risk than tight tuck flaps, but depends on design | If you label the flap, confirm it still closes cleanly |

| Button-lock / press-lock mechanism | A closure that requires a specific motion to open | Can reduce accidental opening; may reduce internal usable space | If child-resistant performance is required where you live |

| Divider insert (5-pack channels) | Separates pre-rolls so they don’t bang together | Stops rattling but can pinch if channels are narrow | Whenever your cones arrive with creases or filters get dented |

| Lamination / foil / spot coating | Surface film or finish | No direct fit change, but affects scuff resistance and recyclability | If you plan to recycle—local rules vary |

The example blank box spec page mentioned earlier calls out optional closures and optional divider inserts in this general style (spec overview).

Step-by-step: measure, calculate, self-test

Tools: a ruler works; a caliper is even better for diameter.

-

Measure 3 samples. Don’t measure just one—pre-roll length can vary slightly.

-

Record total length (L). Measure from the tip to the end of the filter.

-

Record the widest diameter (Dmax). Often near the open end on cone-style pre-rolls.

-

Add clearance. Use

+ 4–8 mmto length and+ 2–4 mmto diameter for a comfortable fit. -

Compare to the compartment (not the outer box). Divider channels are what matter in multi-pack boxes.

-

Do a 30-second self-test. Put the pre-rolls in, close it, shake gently, then open and inspect: crushed tip? new crease? torn paper? If yes, adjust clearance or insert style.

Calculation example (simple “fit math”)

Let’s say your cone measures L = 110 mm. You want 6 mm total extra room so the ends never press.

Required internal length ≈ 110 mm + 6 mm = 116 mm

If your widest point is Dmax = 11 mm, and you want 3 mm total wiggle room:

Required channel width ≈ 11 mm + 3 mm = 14 mm

Cone diameters vary by style; published examples show that opening diameters can land around the ~9–11 mm range for common sizes (example measurements). Your safest move is still measuring your own.

Common misconceptions

-

“If the box says 5-pack, any 5 pre-rolls will fit.” Divider channel length/width is the real limiter.

-

“Blank means no labeling needed.” Blank usually just means unprinted—requirements (warnings, symbols, IDs) may still apply based on your area.

-

“Paperboard = odor-proof.” Paperboard can be sturdy without being airtight.

-

“Child-resistant is a vibe.” Child-resistant has a definition and test method; it’s not just “hard to open.”

Safety & standards

Child-resistant (CR) packaging generally means packaging designed to be significantly difficult for children under five to open, while still usable for adults. The U.S. Consumer Product Safety Commission (CPSC) explains this framework under the Poison Prevention Packaging Act (PPPA). The federal testing procedure for “special packaging” is laid out in 16 CFR 1700.20.

State cannabis rules can add details. As one concrete example, California’s public packaging checklist discusses CR package types (including “initial” vs “multiple-use”) and includes an example warning statement for packaging that is not child-resistant after opening (CDPH checklist PDF). If you’re labeling blank boxes, look up the current rules for your state and product category.

Recyclability: paper and paperboard are commonly accepted by many recycling programs, but coatings/lamination can change what’s accepted. The EPA recommends checking what your local program accepts before placing items in the bin (EPA recycling guidance).

| Label & handling checkpoint | What you’re checking | Fast self-check |

|---|---|---|

| Warning/required info has space | You can place required warnings/IDs without covering key info | Mock it up on paper tape, close the box, confirm nothing rubs off |

| Closure stays secure after labeling | Labels don’t interfere with magnets/tucks/locks | Open/close 10 times; confirm it still shuts fully |

| No crush points | Tips and filters don’t touch hard edges when closed | Insert pre-rolls, close, press lightly, reopen and inspect |

| Rattle control | Pre-rolls don’t bang into each other (or the ends) | Gentle shake test: if you hear clicks, consider an insert or more snug channels |

| Child access risk is addressed | Storage reduces accidental access | Keep out of reach; use locked storage when needed |

FAQ

Quick answers

What does “blank” mean? Usually unprinted/unbranded—so you add your label and any required info.

How much clearance do I need? A practical starting point is 4–8 mm in length and 2–4 mm in width, then confirm with a shake-and-inspect test.

Are paperboard boxes odor-tight? Often not by themselves; focus on the inner containment method if odor control matters.

What makes packaging child-resistant? In the U.S., it’s tied to a definition and a testing approach (PPPA / 16 CFR 1700), and state rules may add specifics.