Practical packaging guide

“Moon rocket–style” infused pre-rolls are often thicker and tackier than a standard pre-roll. That changes what “fits” in real packaging: you need a little more clearance, more separation between pieces, and smarter protection against scuffing or sticking.

Important: If you’re using a supplier listing like this Moon Rockets pre-roll box page, note that it lists custom sizes/shapes and multiple divider insert options rather than one fixed box dimension. Treat your own measurements as the source of truth.

At-a-glance

What to measure (fast):

-

Length (L): end-to-end, including filter tip

-

Max diameter (D): thickest point (infused coatings can add bulk)

-

Surface: dry vs slightly tacky (tacky needs more clearance + less rubbing)

-

Primary protection: bare, inner wrap, or a tube

Starter clearance rules (simple):

-

Pocket length ≈

L + 6–10 mm -

Pocket width ≈

D + 2–4 mm(use the higher end if tacky) -

Between pieces: use dividers so items don’t touch

-

Confirm with a shake test: nothing should scuff or rattle

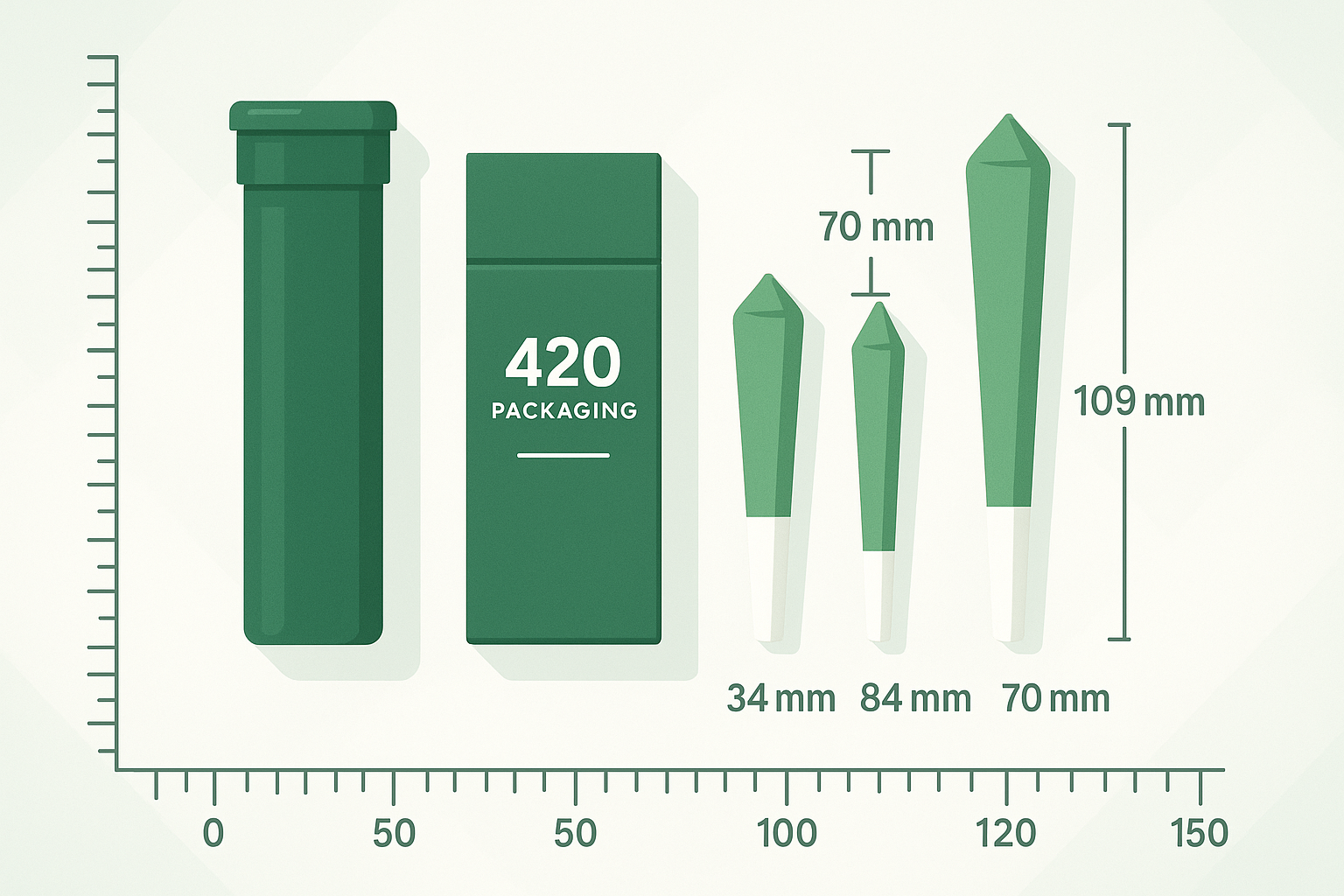

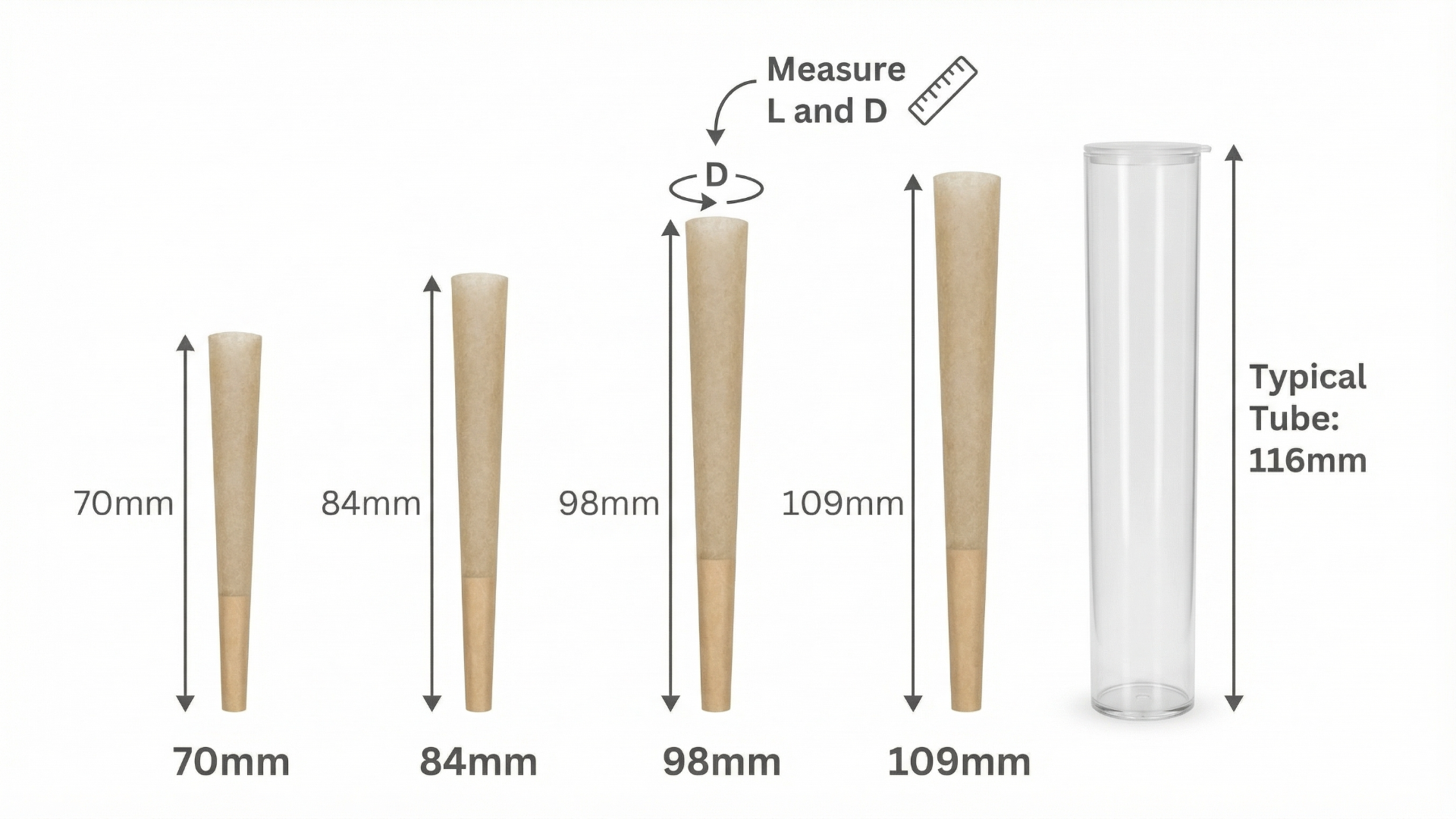

If your pre-rolls are stored in tubes, the “fit” is mostly about tube length and tube diameter. Many common pre-roll cones are in the 70/84/98/109 mm length family (see references in the fit chart), while many king-size tube formats are around 116 mm long depending on the design.

Real-life meaning

A multipack box that’s “too tight” doesn’t just look cramped—it can cause cosmetic damage: edges rub, coatings scuff, and tips deform. A box that’s “too loose” creates movement, which increases rubbing and breakage during transport.

The goal is stable positioning: each pre-roll sits in its own pocket (or its own tube), with enough clearance to avoid sticking—without enough empty space to bounce around.

Fit chart (tables)

Table 1: Common pre-roll sizes + packaging implications

| Common format (reference) | Typical length family | What to size around | Quick “fits?” check | Source links |

|---|---|---|---|---|

| Short / “dogwalker”-style | ~70 mm | Usually the tip and end clearance | Pocket length ≥ L + 6 mm | Cone length families overview |

| 1¼ cone family | ~84 mm | Length + diameter variation between pieces | Pocket width ≥ D + 2–4 mm | Example listing showing 84 mm & other sizes |

| “98 special” family | ~98 mm | Often needs a little more length clearance | Pocket length ≥ L + 8 mm | 98 mm size reference |

| King-size family | ~109 mm | Often paired with ~116 mm tubes | If tubed: tube length + cap hinge clearance | 116 mm tube designed for 109 mm cones |

| Tubed singles (common in retail) | ~116 mm tube length (varies) | Tube outer diameter + hinge/bulge | Box pocket width ≥ tube OD + 2–3 mm | Tube diameter discussion (16 mm common) |

Table 2: Divider insert options (what they solve)

Some vendors explicitly show multiple insert styles for this type of box (for example: no insert, framed divider, and custom divider variants). Inserts matter more for infused/tacky pieces because separation reduces rubbing and sticking.

| Insert approach | What it prevents | When it’s a good idea | What to verify | Example reference |

|---|---|---|---|---|

| No divider insert | Nothing prevents item-to-item contact | Only when every piece is individually tubed | Tube-to-tube rattle under shaking | Divider insert options shown |

| Framed divider insert | Side rubbing, shifting, tip denting | Multipacks with bare pre-rolls or thin inner wraps | Pocket width (D + clearance) for the thickest piece | Framed divider example |

| Custom divider (count-specific) | Rotation and collision during transit | 3/5/10-count boxes where presentation matters | Uniform spacing, easy removal, no tearing | Custom divider variants shown |

Table 3: Quick label + safety checklist (general, non-legal)

| Checkpoint | Why it matters | Simple verification | Helpful standard reference |

|---|---|---|---|

| Child-resistant (CR) claim is accurate | CR is a tested performance claim, not a vibe | If you claim CR, keep test documentation from the closure/packaging system | CPSC guide to special packaging and 16 CFR 1700.15 |

| Tamper-evident (TE) feature is obvious | TE helps consumers see if a package was opened | Seal/indicator must show visible evidence when breached | 21 CFR 211.132 definition |

| Space reserved for required labels | Overcrowding leads to illegible labeling | Print a “label dummy” and confirm it fits flat without covering key seals | FDA TE guidance context |

| Material + coating match handling | Coatings affect scuff resistance and feel | Handle a physical sample and do a rub test with a dry cloth | Supplier spec section |

Step-by-step: measure, calculate, confirm

Step 1) Measure one “worst-case” unit

-

Pick the thickest and stickiest pre-roll in the batch.

-

Measure L (length) and D (max diameter).

-

If you’re using tubes, measure tube length and tube outer diameter (OD), including any hinge or cap bulge.

Step 2) Choose your protection strategy

If pieces are bare (no tube):

-

Plan on a divider insert so pieces don’t touch.

-

Use the higher clearance end (pocket width adds a bit more).

If pieces are tubed:

-

The box becomes a “tube organizer.”

-

Verify tube OD and hinge clearance first.

Step 3) Do the quick fit math (worked example)

Example scenario: 5-count multipack. Each pre-roll is L = 109 mm.

You plan to use tubes that are ~116 mm long (a common pairing for 109 mm cones in some tube formats).

-

Pocket length target:

tube length + 4–8 mm(cap/hinge + easy removal) -

Pocket width target:

tube OD + 2–3 mm -

Internal box length: pocket length + small end padding

-

Internal box width: (pocket width × 5) + (divider thickness × 4) + side padding

Reference for the “109 mm cone + ~116 mm tube” idea:example tube product note.

Step 4) Confirm with a 3-test self-check (10 minutes)

-

Shake test (10 seconds): shake the closed box. You should not hear pieces colliding.

-

Drop test (waist height, onto a book): open the box and check tips/edges for dents or scuffs.

-

Rub test (presentation): remove and reinsert each piece twice. If coatings scuff or stick, increase clearance or upgrade insert separation.

Common misconceptions

-

“Tighter fit looks premium.” Tight fit often means more scuffing and tip deformation in transit.

-

“A bigger box is safer.” Extra empty space increases movement unless inserts lock items in place.

-

“Divider inserts are optional.” They’re the easiest way to prevent contact and improve consistency in multipacks.

-

“Child-resistant and tamper-evident are the same thing.” They are different claims with different expectations.

Safety & standards

Packaging requirements vary by jurisdiction. If you operate in a regulated market, confirm the current rules for your state and product type. Two concepts that are commonly referenced across regulated categories are child-resistant (CR) and tamper-evident (TE).

Child-resistant (CR)

CR packaging is intended to be significantly difficult for children under five to open within a reasonable time, while still usable by adults. The CPSC provides plain-language guidance on “special packaging,” and federal performance specs are described in 16 CFR 1700.15.

Tamper-evident (TE)

TE means there is an indicator or barrier that provides visible evidence to consumers if it’s breached or missing. A clear regulatory definition appears in 21 CFR 211.132 (OTC drug packaging), and the definition is often used as a practical reference in packaging work.

If a supplier listing only states “custom sizes & shapes” (as seen on this Moon Rockets pre-roll box page), request a physical sample or a dieline and validate your own fit with the tests above before committing to final production.

FAQ

How much extra clearance should I add for infused, tacky pre-rolls?

Start by adding a few extra millimeters to pocket width and prioritize divider separation so pieces don’t touch. Then validate with the rub + shake tests.

If I use tubes, do I still need divider inserts?

Often yes for multipacks—tubes can still rattle and scuff unless each tube is held in its own pocket.

Is a “window cut-out” a problem?

It can be fine if the window film doesn’t contact the product. Always verify rub points and keep label space reserved.

What’s the difference between child-resistant and tamper-evident?

Child-resistant is about difficulty for children to open; tamper-evident is about visible evidence that a package was opened.

Do I need one fixed box size?

Not necessarily. Many suppliers offer custom sizes; the practical approach is to standardize around your most common pre-roll format and your “worst-case” diameter.

What’s the fastest way to confirm fit without lab tools?

Measure L/D (or tube OD), then do a shake test, a gentle drop test, and a remove/reinsert rub test.