At-a-glance

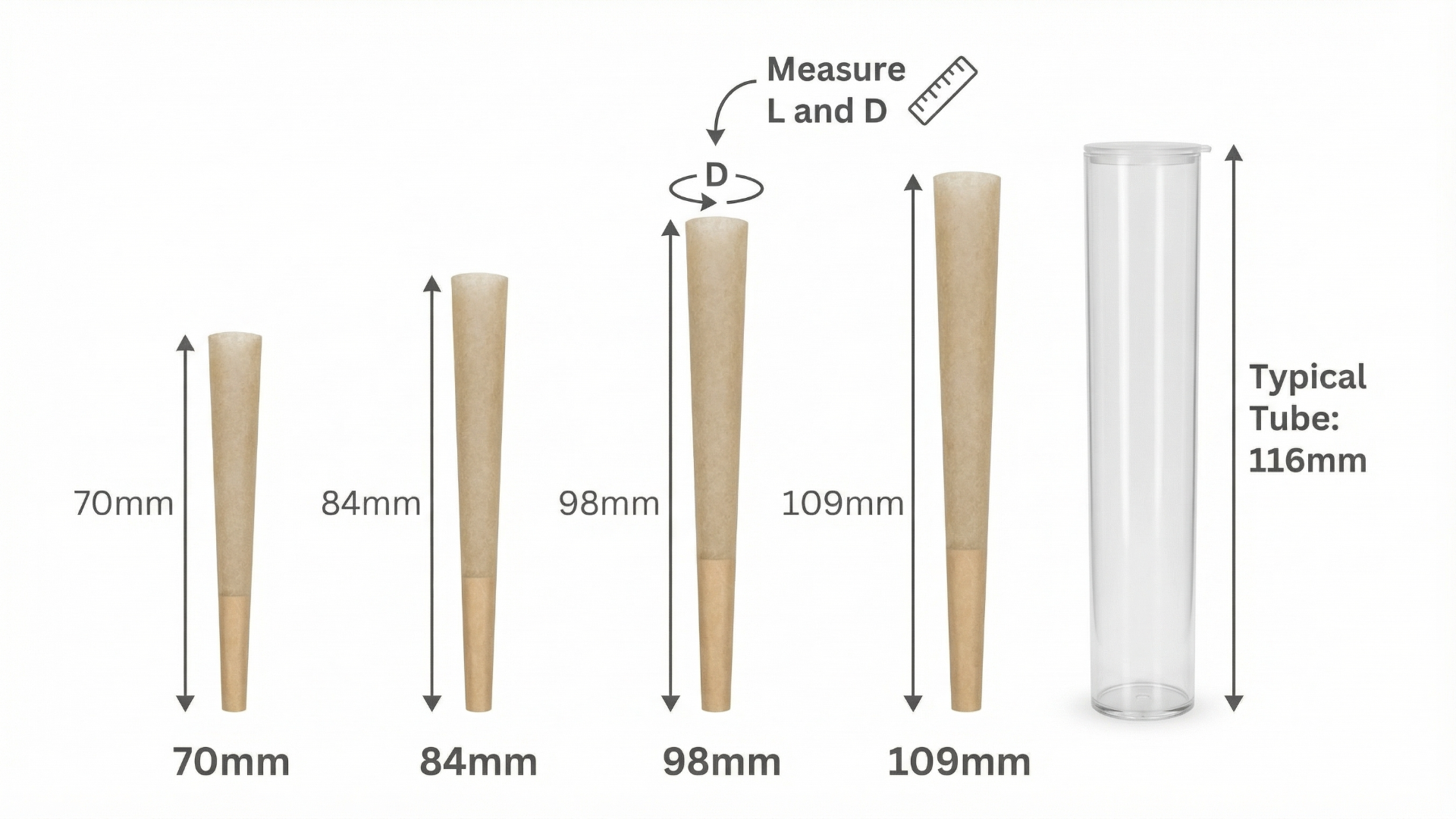

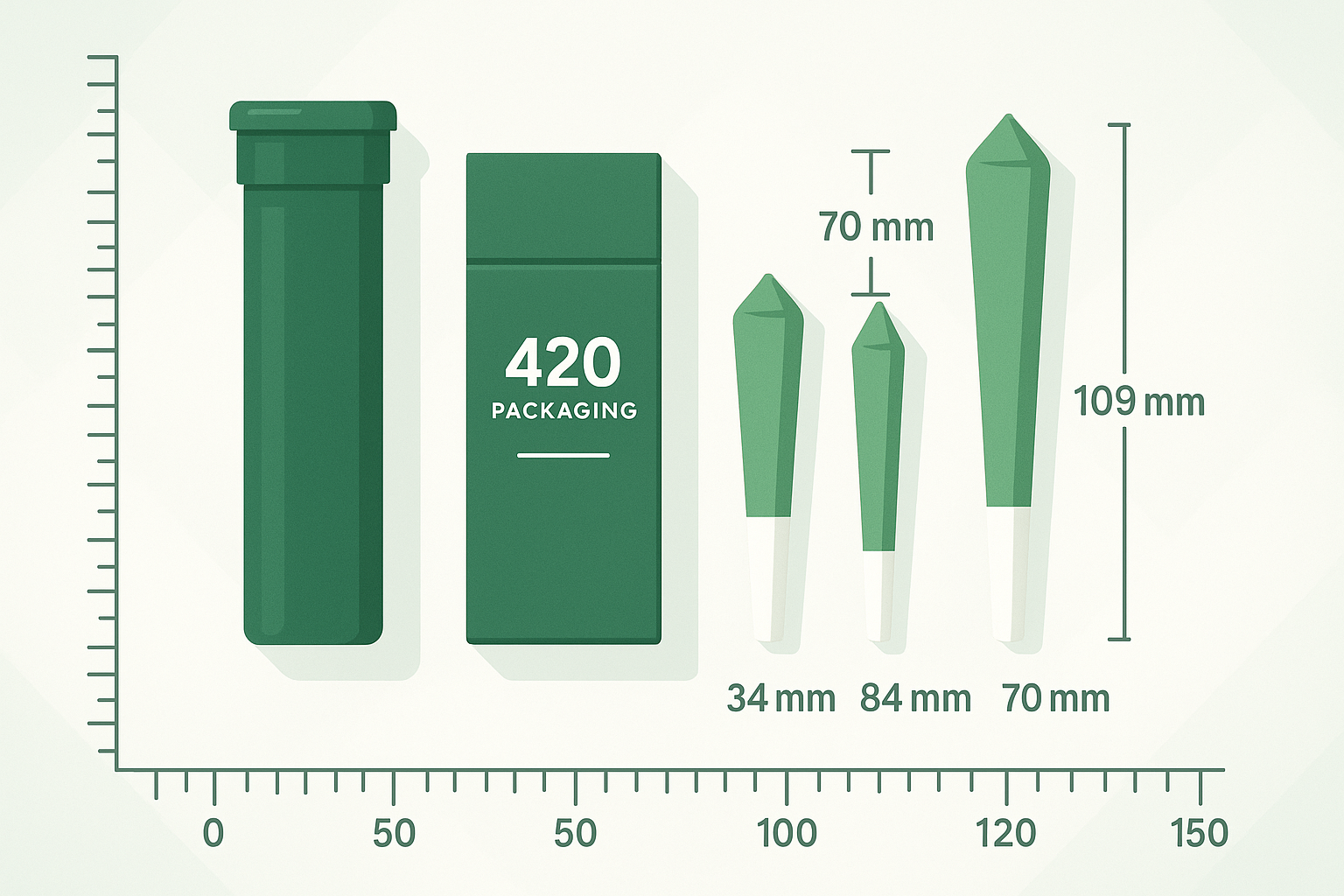

- Fit first Cone length is the starting point. Common lengths are often listed as 70mm, 84mm (1¼), 98mm, 109–110mm (king size), and 120mm. See size references like this cone size chart and manufacturer guides such as Blazy Susan’s size overview.

- Clearance A practical target is 6–10mm extra internal length beyond cone length (more if there’s a hard cap/stopper; less if the insert pocket is deep and protective).

- No rattle Inserts matter. Paperboard or EVA foam pockets help keep cones separated, reduce tip crush, and stop the “shake test” rattle.

- Safety cues “Child-resistant” (CR) and “tamper-evident” (TE) are different features with different goals—don’t assume one implies the other.

- Label reality If a box has a dedicated label panel, you can usually read warnings and symbols more clearly without wrapping labels over seams or edges.

Real-life meaning

If you’ve ever opened a multi-pack and found a bent tip, flattened cone, or a “mystery rattle,” you’ve seen what sizing mistakes look like. Cone boxes aren’t just decoration—they’re a mechanical system: box length, insert pocket size, and closure style work together to keep cones straight and readable.

For example, some packaging specs describe a rigid paperboard box with drawer-style or magnetic flip-top formats, plus paperboard or EVA foam inserts that hold several cones and leave space for compliant labeling. One reference example is this product spec page (rigid paperboard, drawer-style slide box or magnetic flip-top, insert options, capacity ranges, and label space): pre-rolled cones packaging box specification.

Data table: Cone length → box fit targets

Cone makers commonly publish standard lengths (often including 70, 84, 98, 110, 120mm). When you’re judging whether a pack is likely to protect the cone, focus on internal box length and the insert pocket depth—not the outside dimensions. If internal dimensions aren’t listed, you can still self-check the fit with a ruler and the steps below.

| Cone length label | Typical cone length | Suggested internal box length target | Why it helps | Notes for multi-packs |

|---|---|---|---|---|

| 70mm | 70mm | 76–80mm | Prevents tip compression while avoiding extra “bounce room.” | Insert pocket spacing matters more than box length once you go 3+ cones. |

| 1¼ size | 84mm | 90–96mm | Gives room for cone end + minor shifting during transport. | Look for separators that keep cones from touching. |

| 98mm | 98mm | 104–110mm | Common “in-between” length—needs a little headroom or tips can kiss the walls. | Foam pockets can reduce rattle with slimmer cones. |

| King size | 109–110mm | 116–122mm | Longer cones amplify small fit errors; extra clearance avoids bent ends. | For 5-packs, pocket depth + lid/slide stop is key. |

| 120mm | 120mm | 128–135mm | Extra length reduces the chance of compression when the closure is pushed shut. | Any rattle here tends to cause visible “rub marks” on tips. |

Step-by-step: Measure, add clearance, confirm insert

- Measure the cone length. Use a ruler and measure tip-to-end in mm. (If the cone has a hard end-cap, include it.)

- Pick a clearance target. Start with +6 to +10mm internal length beyond cone length.

- Check the insert pocket depth. A deeper pocket can protect tips even with less clearance. A shallow pocket needs more clearance.

- Do the “gentle shake test.” Close the pack and lightly shake once. If you hear cones tapping, the insert or pocket spacing is likely too loose.

- Inspect the tips. Look for flattening, creasing, or “paper fuzz” where a cone rubs the box wall—these are sizing/insert friction clues.

- Scan the label panel. If warning text is wrapped across edges or seams, it can be harder to read and more likely to scuff.

Calculation example

Scenario: You’re checking a king-size cone pack labeled 109–110mm.

Step 1 (measure): Your cone measures 110mm.

Step 2 (clearance): Choose +8mm as a middle-of-the-road target.

Result: Suggested internal length ≈ 110mm + 8mm = 118mm.

Interpretation: If the internal length is closer to ~112–114mm and the insert pocket is shallow, the closure can press the tip. If the internal length is ~125mm but the insert is loose, expect rattle and scuffing.

Data table: Quick self-check checklist

| What to check | How to check (fast) | “Looks good” sign | Common issue it prevents |

|---|---|---|---|

| Internal length vs cone length | Measure cone; estimate clearance (+6 to +10mm target) | Ends don’t touch the box walls when closed | Crushed tips, bent ends |

| Insert pocket snugness | Place cone in pocket; invert briefly (closed, gentle) | Cone stays put without grinding against edges | Rattle, scuffs, loosened fill |

| Separator spacing (multi-pack) | Look between cones; check if paper touches paper | Each cone has its own “lane” | Cones rubbing each other, tip flattening |

| Closure stop / end pressure | Close slowly; feel for resistance right at the end | Closure finishes without “crunch” | Compression at final close |

| Label panel usability | Check if key info crosses seams or folds | Warnings/symbols sit on a flat panel | Unreadable scuffed labels |

| Tamper cue present | Look for a seal/label that must break to open | Obvious “first-open” indicator | Hard-to-notice package opening |

Common misconceptions

- “A bigger box means a bigger cone.” Not necessarily. Some packs are oversized for label panels or inserts, not cone volume.

- “No rattle means perfect protection.” A cone can still be pressed at the ends if internal length is too short or the closure stop is tight.

- “CR and TE are the same thing.” They’re different: CR focuses on child opening resistance; TE focuses on showing if a pack was opened.

- “Outside dimensions tell you the fit.” Inserts and wall thickness can make internal space very different from the outside measurement.

Safety & standards (CR / TE)

Child-resistant (CR): In the U.S., CR (“special packaging”) is defined and discussed by the Consumer Product Safety Commission (CPSC) under the Poison Prevention Packaging Act. The CPSC explains performance expectations (what percentage of children cannot open within defined time windows) in its PPPA special packaging FAQ. The detailed testing procedure is laid out in 16 CFR 1700.20.

International reference: ISO also publishes a child-resistant packaging standard (ISO 8317) describing performance requirements and test methods for reclosable packages: ISO 8317 overview.

Tamper-evident (TE): “Tamper-evident” generally means there’s a visible indicator or barrier to entry so a consumer can tell if the package was opened. A well-known U.S. reference in another regulated category is the FDA rule for OTC drug products: 21 CFR 211.132.

FAQ

What cone lengths are most common for pre-roll packaging?

Common lengths frequently referenced by cone makers include 70mm, 84mm, 98mm, 109–110mm, and 120mm, but exact naming varies by brand.

How much extra clearance should a cone box have?

A practical starting point is 6–10mm beyond measured cone length, adjusted by insert pocket depth and whether the closure presses at the ends.

Why do cones get bent inside otherwise “nice-looking” packaging?

Most often: the internal length is too short, the final close compresses the tip, or the insert pocket is shallow so the cone acts like a lever.

What’s the difference between a drawer-style slide box and a magnetic flip-top?

Drawer-style uses a sliding inner tray; magnetic flip-top uses a hinged lid with a magnet closure. Either can work—fit depends more on internal length and insert design than the outer style.

What do inserts actually do?

They separate cones, reduce movement, and protect tips. Paperboard inserts are light and structured; EVA foam pockets can add grip and cushioning.