Die-cutting for Custom Paper Box

For custom paper boxes, die-cutting is the manufacturing process of cutting different custom shapes out of cardboard and cutting different custom creases into the cardboard. Die-cutting is an essential process in the production of printed paper boxes, printed corrugated boxes, rigid paper boxes and custom paper bags.

E-flute cardboard mailer boxes are typical die-cut paper boxes that are easy to assemble without glue. Die-cut cardboard boxes are flat-packed and shipped.

The Die-cutting Process

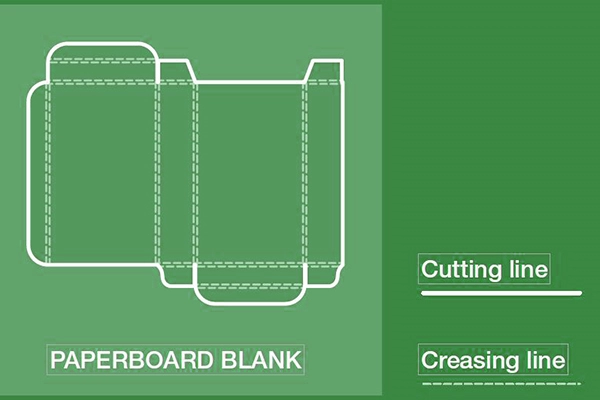

The matrix consists of cut lines and crease lines. During the punching operation, the punching tool reciprocates up and down against the cardboard placed on the machine. After the cycle, the cut cardboard sheets are removed and new sheets are fed into the machine.

There are 5 steps to complete the imprinting process for printed paper boxes.

Step 1: Prepare the mold on your computer using Artios CAD or AutoCAD.

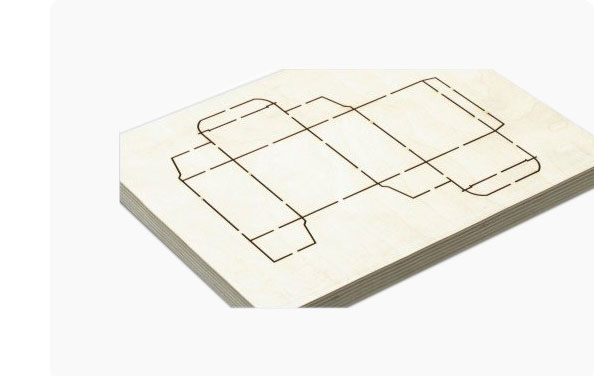

Step 2: Use a laser die cutting machine to etch die lines on the die board.

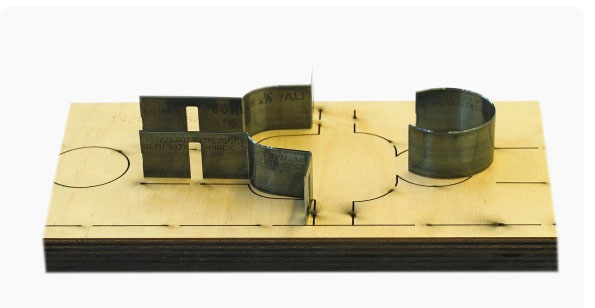

Step 3: Manually or automatically cut and bend the steel line to create the cutting and folding lines, then insert the lines into the mold along the precisely defined lines.

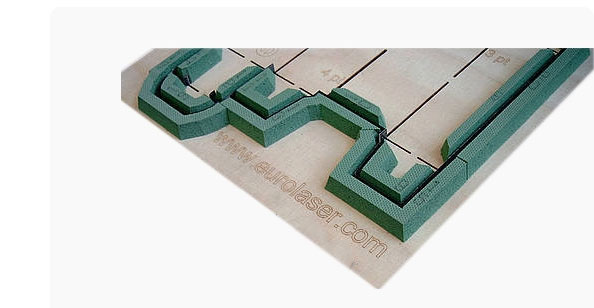

Step 4: Place the ejector rubber along the die line.

Step 5: Assemble the die cutting machine on the press to die cut the carton.

Laser Die-cutting machine

Dieline etched to the die board

Place the cutting rules

Rubbering of the die

Die-cutting Process for Custom Paper Box

Laser cutting is the most complex and unique cutting process. It allows for very fine details and very intricate designs. Almost any corrugated structure can be realized with suitable corrugated board. The working principle is very simple. The original design is etched through a copper stencil placed over a sheet of cardboard. A sharply focused laser beam moves back and forth over the stencil, vaporizing the cardboard wherever there is an etched area.

The purpose of the ejection rubber is to hold the sheet in a fixed position during cutting and eject the cardboard blank from the punch tool. The rubber coating on the die cutter plays a very important role in the quality of the final result. Proper gumming also improves productivity by allowing for higher speeds and minimizing the risk of stalls due to waste loosening in the machine or sheets not ejecting properly from the die. increase.

Cutting

A good custom paper box blank should be clean and free of loose fibers and particles. This gives a precise, clean edge and avoids contamination issues during subsequent handling of the board or during the packaging process.

Setting the right cutting data is critical to achieving clean, clean edges. Because of its strength, toughness, and density, cardboard requires sharp, well-adjusted knives and good die-cutting control. The large force required for cut-through must be well controlled to minimize the so-called "overshoot" of the moving die. Otherwise, the knife will hit the backing plate too hard, which will quickly damage the knife and reduce the quality of the cut edge.

Creasing Line and Cutting Line

Creasing and Cutting

Creasing

Creasing is an operation which facilitates the folding operation of the custom paper box. During creasing, the paperboard is weakened along well defined folding lines, which then act as hinges for folding packaging boxes. It is very difficult to fold paperboard with a good result without creasing.

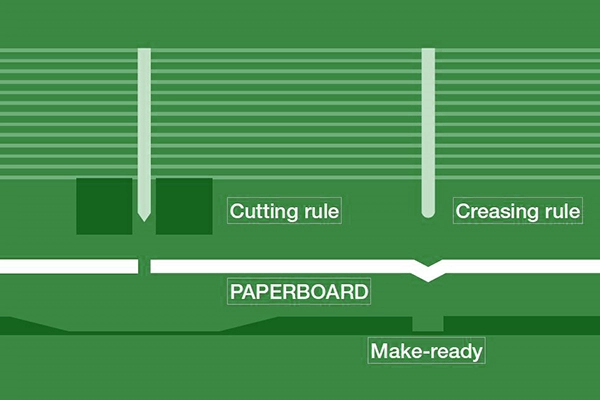

The creasing rules are fitted into the die. When performing the creasing operation, the die reciprocates up and down towards the paperboard, which is placed on the make-ready. After one cycle the creased paperboard sheet is removed and a new one is fed into the machine.

The paperboard is creased by being pressed into a channel or groove in the make-ready. The forces created deform the paperboard in a predetermined way and the deformation is permanent. The result is a reduction in the bending resistance of the crease. The paperboard is therefore weaker along the crease than elsewhere.

Die-cut Paper Box

Die-cut paper box mainly refers to the folding cartons which can be easily setup without the help of the glue flaps. They are widely used in the making of the book folders and corrugated mailer boxes. The Custom E flute corrugated box is one of our most featured products.

Diecut Corrugated Mailer Box

Cannabis Packaging Solutions

As a leading hemp packaging carton supplier, 420 Packaging provides the following packaging solutions

Printing & Finish

With our high-end equipment, the following printing and surface treatment options can make your cannabis packaging box stand out in the market.

Printing Options

Finish Options

Paper Box Design

We can provide free dieline templates for various common mariguana packaging box styles to place your artwork.

Paper Material Options

If you need to customize paper for your customized hemp packaging box, we provide various paper material options to meet your packaging needs.

Inserts and Accessories

At 420 packaging, various plug-ins and accessories can meet your hemp packaging needs, such as plastic handles, PVC, pet plastic windows, sleeves, thermoformed trays, EVA foam, blisters, molded pulp, etc.