Silk Screen Printing

As a leading cannabis packaging box supplier, 420 Packaging offers silk screen printing on customized paper boxes. This printing technology is usually used for cardboard boxes, file folders, kraft paper boxes, paperboard boxes and other special paper printed paper boxes.

The personalized paper box below is a screen printed book mailer with printed inside and out.

Custom paper box with the screen printing

What is Silk Screen Printing?

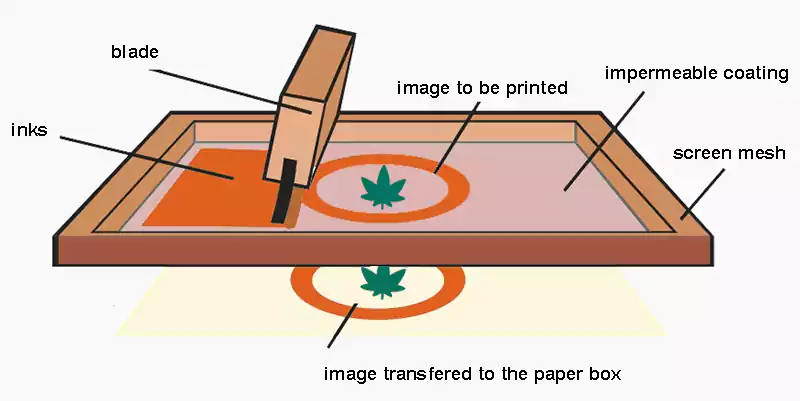

Screen printing uses a screen mesh as a plate to transfer colors to the desired printed area of the paper box. On the other hand, the margins of the paper box are left by applying an impermeable coating to the screen to prevent ink from penetrating. Move the blade or squeegee across the screen to first push the ink into the small opening and then with a quick touch to transfer the ink to the paper box. Only one color is printed at a time, so multiple screens can be used to create full-color printed carton boxes. Screen printing is also known as screen printing because silk was initially used to create the mesh. Later, polyester was invented to replace silk to improve print quality and reduce costs. Polyester is currently the most popular fabric in common use.Other materials include nylon and stainless steel. When printing custom paper boxes, mesh size is a key factor in determining the result and appearance of the finished design of the material.

Screen Printing Process

Screen printing is roughly divided into two processes: preparing a screen mask and then printing.

(1) Put a screen mesh on an aluminum or wooden frame of the same size as the printed paper box.

(2) Apply a photosensitive agent to the screen cloth.

(3) Cover the parts to be printed such as letters and images with a positive mask, and apply UV light to the screen mesh. The coating is hard on the non-printing part.

(4) Rinse the screen mesh with water to wash away the coating on the printed part.

(5) After drying and inspecting the mesh, the screen mask is complete.

(6) Put the screen mesh on the paper box to be printed.

(7) The entire screen is covered with ink, and the small openings in the screen are filled with ink.

(8) The screen briefly touches the surface of the carton and a blade or squeegee is moved over the screen to transfer the ink to the cardboard.

Screen Printing Perspective

In the screen printing process, the image is transferred by penetrating the ink through the openings of the screen fabric, so the ink layer on the paper box is quite thick. In other words, screen printing can be applied to all types of cardboard, including cardboard, thin paper, glossy paper, matte paper, smooth paper, and rough paper.

Custom Screen Printing Paper Box

At 420 Packaging, 90% of the paper boxes are Lito or UV printed. However, when it comes to custom paper boxes made of special black paper or cardboard like kraft paper, these printing methods stop working because the ink layer is too thin to be seen. Screen printing method is usually used for printing for these special boxes.

Custom Screen Printed Paper Box

As you can see, the bookmailer has a white Pantone color print on the outside of the kraft paper and a blue Pantone color print on the inside of the white kraft paper.

Screen Printing Details

Screen printing is perhaps the most versatile of all printing processes. You can print on a variety of materials including paper, cardboard, plastic, glass, metal, fabric, nylon, cotton and many other materials. Common products in the screen printing industry include custom paper boxes, posters, labels, stickers, signs, all kinds of fabrics and electronic circuit boards. The advantage of screen printing over other printing methods is that the press can print on materials of any shape, thickness and size. 420 Packaging typically uses a litho offset printing process to create high graphic prints on custom paper boxes, but some paper substrates do not work. Then use screen printing.

A key feature of screen printing on corrugated boxes is that thicker inks can be applied to the corrugated board than other printing techniques. This allows for very interesting effects that are not possible with other printing methods. Due to the simple application process, screen printing can use a wider range of inks and dyes than other printing processes. In fact, the spot UV finish is screen printed onto paper boxes due to its special thick coating properties.

With the improvement of production rate, the use of screen printers is starting to increase. This is the result of the development of automatic rotary screen printers, improved dryers and UV technology. curing ink. Major chemicals used include screen emulsions, inks and solvents, surfactants, corrosives, and oxidizing agents used in screen regeneration. The inks used vary greatly in their formulation (GATF 1992b).

Cannabis Packaging Solutions

As a leading hemp packaging carton supplier, 420 Packaging provides the following packaging solutions

Printing & Finish

With our high-end equipment, the following printing and surface treatment options can make your cannabis packaging box stand out in the market.

Printing Options

Finish Options

Paper Box Design

We can provide free dieline templates for various common mariguana packaging box styles to place your artwork.

Paper Material Options

If you need to customize paper for your customized hemp packaging box, we provide various paper material options to meet your packaging needs.

Inserts and Accessories

At 420 packaging, various plug-ins and accessories can meet your hemp packaging needs, such as plastic handles, PVC, pet plastic windows, sleeves, thermoformed trays, EVA foam, blisters, molded pulp, etc.